Date: February, 2023 | Category: Compliance | Author: Hana Trokic

The Food and Drug Administration (FDA) sets strict labeling requirements and guidelines for food, drugs, cosmetics, and medical devices to name a few. The goal of these rules and regulations is to ensure that consumers have accurate and complete information about the products they purchase and consume.

These guidelines cover everything from product ingredients and information, to labeling and packaging requirements. It’s important for manufacturers and distributors to understand and comply with these regulations to avoid potential legal and financial downfalls along with ensuring the complete safety of the consumer.

This post will provide an overview of the FDA’s labeling requirements for specific markets and offer resources on how to stay FDA compliant.

Want to learn more about compliance, proofreading, and quality control? Read more content from GlobalVision here!

What is the FDA?

The Food and Drug Administration, otherwise known as the FDA, is responsible for protecting public and consumer health by ensuring the safety, efficacy, and security of food, drugs, medical devices, cosmetics, and more.

A federal agency within the U.S. Department of Health and Human Services, the FDA is responsible for:

- Reviewing and approving new foods, drugs, cosmetics, and medical devices before they are sold to the public

- Inspecting companies that make and distribute food, cosmetics, drugs, and medical devices

- Monitoring the safety of food, drugs, cosmetics, and medical devices after they have been approved and are on the market

- Providing information to the public about the safety and effectiveness of food, drugs, cosmetics, and medical devices

- Regulating the labeling and advertising of food, drugs, cosmetics, and medical devices

- Enforcing laws that protect consumers from unsafe or misbranded products

What are FDA Labeling Requirements?

FDA labeling requirements are guidelines and regulations set for the labeling of food, drug, cosmetics, and medical device products.

These guidelines ensure that consumers have accurate and complete information about the products they purchase.

The FDA labeling requirements cover a wide range of information, including:

- Packaging and labeling requirements for specific products.

- Ingredient list

- Health claims and nutrient content claims

- Warning statements where applicable

- Nutrition information for food labeling

- Allergens

Manufacturers and distributors must thoroughly understand and comply with all FDA labeling requirements to ensure a safe and reliable product along with getting their products to market faster. They also need to keep updated with FDA regulations as they change over time and manufacturers want to ensure the consistent compliance of their products.

Historical Context of FDA Labeling Requirements

The history of FDA labeling requirements goes back to the late 19th century when the U.S. government first began to regulate the safety and purity of food and drugs. The first federal food and drug law, the Pure Food and Drug Act of 1906, was passed in response to public concern about the safety of food and drugs that were being sold across state lines.

This law required that food and drugs be labeled with accurate information about their contents and prohibited the sale of misbranded or adulterated products.

Over the years, the FDA has continued to update and strengthen its labeling regulations to keep pace with advances in science and technology, as well as changes in consumer preferences.

For example, in the 1960s, the FDA introduced regulations requiring that food labels include nutritional information. In the 1990s, the FDA began to require that food labels list the presence of major food allergens.

The most recent major update to the FDA’s labeling regulations came in 2016 when the agency issued the final rule for the Nutrition Fact Label for packaged foods. This rule, which went into effect in 2020, requires that food labels list the amount of added sugars and gives manufacturers the option to declare the amount of potassium and vitamin D in their products.

In addition to these, the FDA also has updated regulations for different products like dietary supplements, cosmetics, medical devices, tobacco, and others.

FDA Labeling Requirements for Different Markets

FDA labeling requirements vary from market, product, and commodity. Each product, depending on its intention of use, has its own set of requirements that manufacturers need to follow.

The FDA differentiates between markets so that proper instructions and specific requirements can be given to ensure consumer and product safety and avoid recalls, and potential financial losses.

The main markets that will be analyzed in this post are:

- FDA labeling requirements for medical devices

- FDA labeling requirements for drugs

- FDA cosmetics labeling requirements

- FDA labeling requirements for food

Following FDA requirements is complicated. We make it easy.

Keep up with the latest in compliance, quality control, and proofreading by signing up for our newsletter.

FDA Labeling Requirements for Medical Devices

Medical devices can range from simple to complex. Regardless of its complexity, there is a constant amongst them all. They all need to be tested and approved to meet FDA requirements and compliance.

Types of Medical Devices and Their Regulations

A medical device can range from the simplest household item found in everyone’s pantry, like a band-aid, to more complex technology like an x-ray machine. Regulatory authorities globally have put into place risk classifications that group devices into categories based on their potential harm if misused, the complexity of the device, and certain use characteristics.

These classifications are essential to ensure safety and ease the marketing and placement of devices. It also sets a standard for testing where officials know, according to classification, how much testing a device needs to undergo to be deemed safe and ready for patient use.

Medical Device Classification

In the United States, the FDA has classified medical devices into three categories based on the level of control needed to ensure the safety of use. The classifications are:

- Class I – Low risks: Includes devices such as bandages, toothbrushes, floss, and hospital beds. Only requires general controls.

- Class II – Medium Risk: Includes contact lenses, pregnancy tests, and catheters. Requires general controls as well as pre-market notifications

- Class III – High Risk: Includes respirators, prosthetics, and pacemakers. Requires all general controls along with special controls and pre-market approval.

Regulations and Standardizations

Regardless of their classification, it’s important that all medical devices adhere to a certain set of regulations and standardizations. Much like pharmaceuticals, medical devices are treated with similar rigor and are highly regulated.

The FDA offers a detailed overview of all the regulations devices need to follow in order to be deemed fit for use by the general public. The International Organization for Standardization (ISO) sets the standards and convenes them for ease of implementation in the industry.

Some regulations that are put in place for medical devices include:

- Establishment registration

- Medical device listing

- Pre-Market notification

- Pre-Market approval

- Quality system regulation

- Labeling

- Medical device reporting

Labels and Labeling

The FDA defines a label as a “display of written, printed, or graphic matter upon the immediate container of any article” or “all labels and other written, printed, or graphic matter.”

As such, labels are the first point of contact for information for many medical practitioners, patients, and consumers, and need to be accurate to avoid confusion or life-threatening consequences.

The FDA breaks down label regulations for medical devices and clearly defines them by the following:

- General device labeling

- Use of symbols

- Unique device identification

- Good manufacturing practices

- General electronic products

These regulations are in place to primarily ensure that the products and devices in question are being used as they are intended and that the safety of those using them is guaranteed.

For an in-depth look at how you can comply with FDA labeling requirements for medical devices, read our thorough blog post here.

FDA Drug Labeling Requirements

For highly regulated industries like pharmaceuticals, following FDA drug labeling requirements is one of the most crucial aspects of the product lifecycle.

The accuracy of drug labels ensures that patients and consumers are being given proper instructions and dosages of a prescribed drug. Label accuracy also ensures that pharmaceutical companies avoid life-threatening side effects for their consumers, large recalls, and colossal financial downfalls.

The Highly Regulated Pharmaceutical Industry

When it comes to drug labeling, the FDA’s primary purpose and concern are to ensure patient safety and provide healthcare professionals with information about the drug and how it should be prescribed.

Some of the FDA’s drug label requirements include:

- Highlights (a concise summary of label information)

- Full prescribing information

- Recent Major Changes

- Indications and Usage

- Dosage & Administration

- Dosage Forms & Strengths

- Contraindications

- Warnings & Precautions

- Adverse Reactions (listing of most common adverse reactions)

- Drug Interactions

For more information about the importance of FDA drug labeling requirements, read our comprehensive blog post.

FDA Cosmetic Labeling Requirements

All cosmetics marketed globally must comply with provisions set by the governing body of that specific country or region. In the United States, the FDA is responsible for regulating cosmetic labeling with the main goal of ensuring consumer safety and avoiding fraudulent and deceptive statements.

What are Cosmetics?

The FDA defines cosmetics as “articles intended to be applied to the human body for cleansing, beautifying, promoting attractiveness, or altering the appearance without affecting the body’s structure or functions.“

Some products that fall under this category include creams, lotions, perfumes, make-up, shampoos, toothpaste, and deodorants.

While it may seem clear what cosmetics are, manufacturers need to be careful when creating, labeling, and marketing their cosmetic products to ensure they fit under the FDA’s definition and regulations.

If not appropriately labeled, some claims may cause a product to fall under the category of a drug, in which case it has to undergo a set of regulations that differ significantly from cosmetics.

Though sometimes lines can be blurred, manufacturers must understand the difference between cosmetics and drugs and label their products accordingly to avoid potential complications, fines, and recalls.

Cosmetic Labeling

Cosmetic products distributed in the United States must comply with all label regulations established by the FDA. Labels are otherwise considered all written, printed, or graphic matter on or accompanying a product.

The FDA requires that all label statements appear on the inside and outside of the packaging and wrapping.

It is also important to note that false and misleading claims and wrongly labeled products that do not follow FDA cosmetic labeling requirements and regulations may be subject to regulatory action.

How to Correctly Label Cosmetics

To ensure the proper placement of cosmetics on the market and that consumers use them appropriately, manufacturers need to take note of adequate labeling requirements and adhere to them as strictly as possible.

A cosmetic label must contain the following:

- Product identity

- Net contents

- Declaration of Ingredients

- Label warnings

If you want to learn all about FDA cosmetic labeling requirements and how to meet them with complete ease, read our detailed blog post.

FDA Labeling Requirements for Food

Food labels have very defined rules regarding how they should be placed on packages and containers.

General Food Labeling Requirements

Generally speaking, there are two ways to label food:

- Place all required label statements on the front of the label panel.

- Place certain specified label statements on the principal display panel (PDP, or the part of a food label that is most likely to be displayed to the customer when for sale – the front label on a product) and other labeling on the information panel.

No matter the food product, the PDP must display specific information critical for consumers. This includes the food name and the net quantity statement. Food must also include the information panel, which is usually placed to the right of the PDP.

The information panel refers to statements that are generally required to be placed together. They usually include information such as the name and address of the manufacturer, ingredient list, nutrition labeling, and allergy labeling.

It is also important to note that label standardizations must be followed to ensure consistent and easy-to-read labels.

The FDA requires that you use a prominent print size and that the font is clear and legible through specified letter height. Additional formatting is also detailed in FDA guidelines to ensure that text is easy to read on different backgrounds and artwork.

Manufacturers must also ensure that all of their food labels contain the following:

- Name of food

- Net quantity of contents statements

- Ingredients list

- Food allergen labeling

- Nutrition labeling

- Nutrition content claims

Want to take a deep dive into FDA food labeling requirements? We have the blog post just for you.

How to Meet FDA Labeling Requirements

Regardless of the food, drug, cosmetic, or medical device you want to send out to market, there are constants among them all that help ensure their safety and quality.

Best Practices for Preparing Labels for FDA Review

There are several best practices for preparing labels for FDA review:

- Ensure that the label accurately reflects the contents of the product and that it meets all legal requirements for labeling.

- Include all required information, such as the product’s name, ingredients, and nutritional information when needed.

- Provide detailed information about the product, including how to use it, storage instructions, and any other relevant information.

- Make sure that any health or safety claims are supported by scientific evidence and are not misleading.

- Provide allergen information, if any, on the packaging when needed.

- Use clear and conspicuous language that is easy to read and understand.

- Use appropriate formatting and layout to make the label easy to read, including using contrasting colors and appropriate font sizes.

- Make sure that the label is consistent with any advertising or promotional materials for the product.

- Provide contact information for the manufacturer or distributor, such as address, phone number, or website.

The Importance of Label Accuracy

When we look at highly regulated products such as pharmaceuticals, cosmetics, and medical devices, the first thing our eyes go to, is the label. This is where we know we will find all the information needed about that said product.

The information stated on that very piece of content determines whether or not a consumer will find the product suitable and reliable enough to purchase and use. Because of this, the accuracy of labels should be of high priority.

Label accuracy is crucial as it details the products:

- Safety: Accurate labels ensure that consumers are aware of any potential hazards or allergies associated with the product, which can help prevent harm or injury.

- Legal compliance: Accurate labels help ensure compliance with these regulations and reduce the risk of fines or legal action.

- Trust and credibility: Accurate labels help build trust and credibility with consumers, as they demonstrate that a company is committed to providing honest and transparent information about its products.

- Liability: Inaccurate labeling can lead to product liability claims from consumers who have suffered harm or injury as a result of using a product.

In order to have only the highest quality products making it into the hands of consumers, label accuracy should be a top priority throughout the entire product development process. It is important to proof, check, and, review, labels to ensure that they are accurate, complete, and up-to-date.

Common Label Mistakes to Avoid

As inaccurate labels can lead to disastrous consequences for highly regulated industries, proofreading, reviewing, and checking labels should be a thorough and precise process. Mistakes should be avoided by any means necessary.

Some common label mistakes that manufacturers should avoid include:

- Incorrect or incomplete information: Failing to provide all required information or providing incorrect information on a label.

- Poor readability: Using small font sizes, poor contrast, or a confusing layout can make it difficult for consumers to read and understand labels.

- Inadequate allergen labeling: Failing to properly label potential allergens can lead to serious health consequences for certain individuals.

- Outdated information: Failing to update a label with new information, such as changes in ingredients or nutritional information, can be misleading to consumers.

- Non-compliance with regulatory requirements: Labels must comply with all applicable laws and regulations, such as those related to nutrition, health and safety claims, and ingredient labeling.

- Misleading or false claims: Making false or misleading claims on a label can result in legal action and damage to a company’s reputation.

Best Practices for Maintaining FDA Label Compliance

With many rules, regulations, and requirements to follow, it’s no surprise that such heavy importance is placed on label accuracy. For perspective, in drug labeling, it is estimated that over 50% of medication use errors are associated with poor labels.

Though this includes patient misunderstandings, it is generally believed that implementing standardizations such as text, language, typography, and other display standards will drastically reduce errors in drug labels.

Along with patient safety, it is also important to note that labeling errors lead to significant recalls and financial losses, which are more frequent than one would think.

Clinically important drug recalls occur approximately once per month in the United States. For perspective on just how significant these financial impacts can be, Johnson and Johnson lost roughly $600 million in sales after closing a distribution site due to a recall.

Because of this, best practices should be put in place to ensure that labels are accurate while maintaining manufacturing and distribution efficiency and speed.

One certain method that ensures label accuracy is the implementation of automated quality control, or more precisely, a file comparison tool to check content and labels with complete ease and efficacy.

What is File Comparison Technology?

Content for highly regulated products is produced at such rates and numbers that companies need to turn to technology to help ensure the accuracy of their content and labeling along with all technical documentation.

In other words, file comparison technology is the ideal solution they are looking for.

File comparison technology proofreads documents and files in seconds. The software works by overlaying two files to find discrepancies between the two. No matter how small the errors or differences may be, the software will detect them and pinpoint their exact location on the file.

The software can detect errors in copy and artwork that is nearly impossible to see with the naked eye. Using a document comparison tool, errors and differences can be easily found in text, graphics, barcodes, braille, print, and color.

The result is proofread and error-free labels and packaging in record time – every time.

By introducing file comparison technology to your proofreading and reviewing processes, quality control departments in regulated industries can avoid unnecessary and hasty product mistakes that can be easily corrected and avoided.

The technology gives manufacturers confidence that their products and accompanying labels reach the hands of consumers in pristine condition – down to the last period.

Find out more about how file comparison technology can help quality control teams in regulated industries.

Your New Automated Solution

Many large global corporations in highly regulated industries have yet to implement new technologies that increase workflow efficiency.

In some cases, many still rely on manual and labor-intensive proofreading and reviewing processes prone to mistakes, leaving huge potential for operations to be optimized and streamlined for maximum efficiency.

Automated quality control or a file comparison tool inspects content and artwork with complete ease, lightning speed, and increased accuracy.

To keep up with increasing global consumer demands, regulated industries create an immeasurable amount of products, each with its own packaging, labeling, and documentation. This content must be meticulously reviewed and proofread to ensure that the final product is error-free.

Manually proofreading this amount of content is not an efficient solution for companies that need to keep up with growing demands. File comparison software offers a foolproof solution to ensure all this generated content is checked and proofread perfectly.

This advancement in proofreading processes eliminates the need for manual document inspections and leaves it up to technology. The software conducts digital checks for discrepancies in text, spelling, graphics, color, and more.

The software conducts thorough inspections in a fraction of the time and ensures that labels and content are 100% accurate before going out to the hands of patients and consumers.

This technological advancement ultimately increases productivity and workflow efficiency and offers endless benefits unmatched by manual inspections. Not only does automated proofreading software help ease the proofreading process, it simply makes proofreading better.

Keep Up with FDA Labeling Requirements

If you want to keep up with FDA labeling requirements with complete ease, switch to automated quality control. A trusted technology, GlobalVision’s innovative automated solutions have been solving problems for regulated industries globally for over thirty years.

By using GlobalVision to eliminate time-consuming and inaccurate manual checks, the largest pharma companies worldwide cut review times by 89%. Just by making the simple switch to automated quality control, top companies got critical healthcare products into the hands of consumers faster and with complete confidence that their labels and content are 100% accurate and FDA compliant.

To name only a few, GlobalVision has helped:

Ensuring that you meet all FDA drug labeling requirements is far from easy. Yet, through the simple introduction of automated quality control, companies can rest assured that they are drastically eliminating the risk of human error, getting their product to market faster with fewer revision cycles, and reducing the risk of costly recalls and misprints.

Ready to Automate Your Workflows?

To ensure market success and error-free, perfect labels, regulated industries must streamline their quality control processes. The simple Implementation of file comparison technology helps teams create flawless labels, speeds up the content creation process and revision times, and gets products to market in record time.

The benefits a file comparison tool brings to manufacturers are countless and, in most cases, are a crucial company resource. The only way manufacturers can be completely confident that their content and products are error-free is through fast, accurate, and trusted software such as file comparison technology.

Ready to step into the world of automated proofreading? Request a demo of our innovative text comparison software and see how this technology can revolutionize your everyday business practices. Transform your quality control processes with GlobalVision’s cloud-based quality inspection tool.

Also, to learn more about how technology can help manage regulatory compliance, check out GlobalVision’s guide Digital Transformation for Pharmaceutical Packaging Quality.

———————————————————————————————————————————————————

Related Articles:

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.

Introducing Our Latest Release: Verify 2023.1

Date: February, 2023 | Category: Proofreading | Author: Hana Trokic

Ready for a new, heightened Verify experience?

Our first release of the year is here! Verify 2023.1 makes automated proofreading even more effortless than before. This new release boasts new features and capabilities that enhance the overall user and admin experience, ensuring complete ease of use while increasing the accuracy and efficiency of your quality inspections.

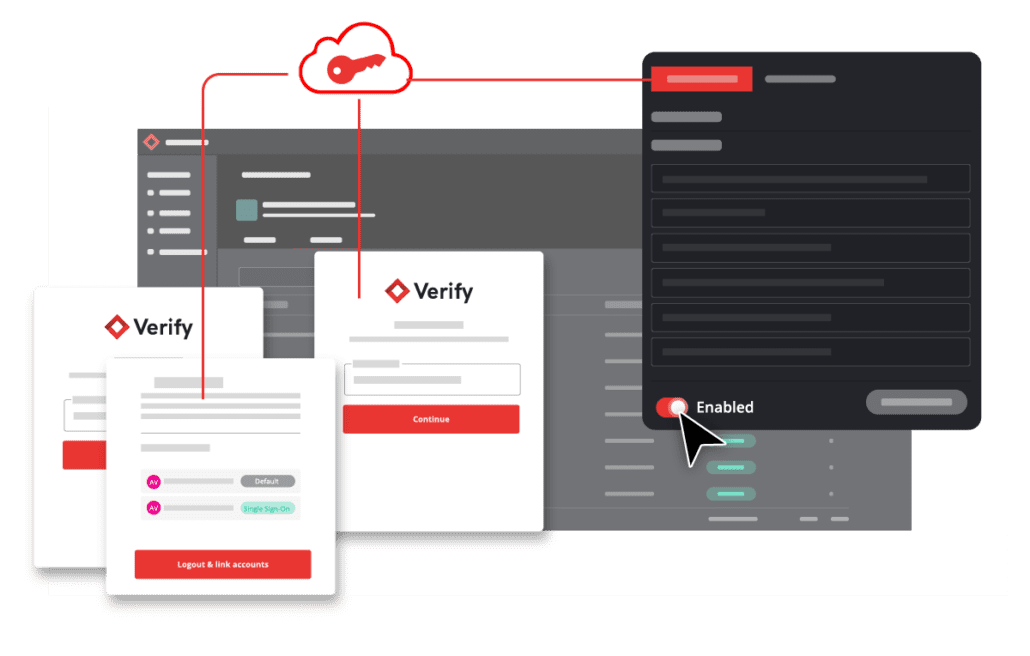

Verify, Our Cloud-Based Proofreading Software

Verify is cloud-based proofreading reinvented that ensures error-free content with the utmost ease of use. With Verify’s automated proofreading platform, you can streamline your work processes and produce higher-quality content in record time.

What to Expect From Our Latest Release

Verify 2023.1 includes new advancements that will heighten ease of use, security, and accuracy.

The most impactful feature of this release is the introduction of SSO (Single Sign On), which enables users to securely authenticate with multiple applications by using just one set of credentials. The following SSO platforms will be supported: Azure, Okta, and Ping Federate. SSO also removes the overhead of managing the software, reduces security concerns, and minimizes the risk of implementing the software.

Additionally, this latest version broadens the capabilities of Text Inspection 2 and allows for smarter difference grouping which results in fewer false positives when reviewing results.

Here’s what to look forward to with Verify 2023.1

Who Can Benefit From This Release?

While Verify is built for regulatory affairs and promotional teams in all industries, Verify will prove to be especially beneficial for those working in the enterprise pharmaceutical, consumer packaged goods, as well as marketing, and advertising industries.

Whether you work in a creative or more technical department, Verify 2023.1 is sure to heighten your proofreading and revision processes. Through ease of use, convenience, and simplicity, our all-encompassing comprehensive platform is a valuable tool for all professional teams.

Heighten your Proofreading Experience

Our new capabilities were built with the end user in mind to ease their everyday proofreading and quality control processes.

Whether you are saving time and increasing security through our Single Sign On feature or are enjoying fewer false positives and a more streamlined inspection process, Verify 2023.1 brings you an overall enhanced proofreading experience.

If you are interested in a more personalized overview of Verify and how it can help your team specifically, request a demo here or take advantage of a free trial today.

Make the switch to automated quality control and discover how Verify can streamline your workflows and benefit your team’s overall quality control processes.

———————————————————————————————————————————————————

Related Resources:

Your Complete Guide to Meeting FDA Labeling Requirements

Date: February, 2023 | Category: Compliance | Author: Hana Trokic

The Food and Drug Administration (FDA) sets strict labeling requirements and guidelines for food, drugs, cosmetics, and medical devices to name a few. The goal of these rules and regulations is to ensure that consumers have accurate and complete information about the products they purchase and consume.

These guidelines cover everything from product ingredients and information, to labeling and packaging requirements. It’s important for manufacturers and distributors to understand and comply with these regulations to avoid potential legal and financial downfalls along with ensuring the complete safety of the consumer.

This post will provide an overview of the FDA’s labeling requirements for specific markets and offer resources on how to stay FDA compliant.

Want to learn more about compliance, proofreading, and quality control? Read more content from GlobalVision here!

What is the FDA?

The Food and Drug Administration, otherwise known as the FDA, is responsible for protecting public and consumer health by ensuring the safety, efficacy, and security of food, drugs, medical devices, cosmetics, and more.

A federal agency within the U.S. Department of Health and Human Services, the FDA is responsible for:

What are FDA Labeling Requirements?

FDA labeling requirements are guidelines and regulations set for the labeling of food, drug, cosmetics, and medical device products.

These guidelines ensure that consumers have accurate and complete information about the products they purchase.

The FDA labeling requirements cover a wide range of information, including:

Manufacturers and distributors must thoroughly understand and comply with all FDA labeling requirements to ensure a safe and reliable product along with getting their products to market faster. They also need to keep updated with FDA regulations as they change over time and manufacturers want to ensure the consistent compliance of their products.

Historical Context of FDA Labeling Requirements

The history of FDA labeling requirements goes back to the late 19th century when the U.S. government first began to regulate the safety and purity of food and drugs. The first federal food and drug law, the Pure Food and Drug Act of 1906, was passed in response to public concern about the safety of food and drugs that were being sold across state lines.

This law required that food and drugs be labeled with accurate information about their contents and prohibited the sale of misbranded or adulterated products.

Over the years, the FDA has continued to update and strengthen its labeling regulations to keep pace with advances in science and technology, as well as changes in consumer preferences.

For example, in the 1960s, the FDA introduced regulations requiring that food labels include nutritional information. In the 1990s, the FDA began to require that food labels list the presence of major food allergens.

The most recent major update to the FDA’s labeling regulations came in 2016 when the agency issued the final rule for the Nutrition Fact Label for packaged foods. This rule, which went into effect in 2020, requires that food labels list the amount of added sugars and gives manufacturers the option to declare the amount of potassium and vitamin D in their products.

In addition to these, the FDA also has updated regulations for different products like dietary supplements, cosmetics, medical devices, tobacco, and others.

FDA Labeling Requirements for Different Markets

FDA labeling requirements vary from market, product, and commodity. Each product, depending on its intention of use, has its own set of requirements that manufacturers need to follow.

The FDA differentiates between markets so that proper instructions and specific requirements can be given to ensure consumer and product safety and avoid recalls, and potential financial losses.

The main markets that will be analyzed in this post are:

Following FDA requirements is complicated. We make it easy.

Keep up with the latest in compliance, quality control, and proofreading by signing up for our newsletter.

FDA Labeling Requirements for Medical Devices

Medical devices can range from simple to complex. Regardless of its complexity, there is a constant amongst them all. They all need to be tested and approved to meet FDA requirements and compliance.

Types of Medical Devices and Their Regulations

A medical device can range from the simplest household item found in everyone’s pantry, like a band-aid, to more complex technology like an x-ray machine. Regulatory authorities globally have put into place risk classifications that group devices into categories based on their potential harm if misused, the complexity of the device, and certain use characteristics.

These classifications are essential to ensure safety and ease the marketing and placement of devices. It also sets a standard for testing where officials know, according to classification, how much testing a device needs to undergo to be deemed safe and ready for patient use.

Medical Device Classification

In the United States, the FDA has classified medical devices into three categories based on the level of control needed to ensure the safety of use. The classifications are:

Regulations and Standardizations

Regardless of their classification, it’s important that all medical devices adhere to a certain set of regulations and standardizations. Much like pharmaceuticals, medical devices are treated with similar rigor and are highly regulated.

The FDA offers a detailed overview of all the regulations devices need to follow in order to be deemed fit for use by the general public. The International Organization for Standardization (ISO) sets the standards and convenes them for ease of implementation in the industry.

Some regulations that are put in place for medical devices include:

Labels and Labeling

The FDA defines a label as a “display of written, printed, or graphic matter upon the immediate container of any article” or “all labels and other written, printed, or graphic matter.”

As such, labels are the first point of contact for information for many medical practitioners, patients, and consumers, and need to be accurate to avoid confusion or life-threatening consequences.

The FDA breaks down label regulations for medical devices and clearly defines them by the following:

These regulations are in place to primarily ensure that the products and devices in question are being used as they are intended and that the safety of those using them is guaranteed.

For an in-depth look at how you can comply with FDA labeling requirements for medical devices, read our thorough blog post here.

FDA Drug Labeling Requirements

For highly regulated industries like pharmaceuticals, following FDA drug labeling requirements is one of the most crucial aspects of the product lifecycle.

The accuracy of drug labels ensures that patients and consumers are being given proper instructions and dosages of a prescribed drug. Label accuracy also ensures that pharmaceutical companies avoid life-threatening side effects for their consumers, large recalls, and colossal financial downfalls.

The Highly Regulated Pharmaceutical Industry

When it comes to drug labeling, the FDA’s primary purpose and concern are to ensure patient safety and provide healthcare professionals with information about the drug and how it should be prescribed.

Some of the FDA’s drug label requirements include:

For more information about the importance of FDA drug labeling requirements, read our comprehensive blog post.

FDA Cosmetic Labeling Requirements

All cosmetics marketed globally must comply with provisions set by the governing body of that specific country or region. In the United States, the FDA is responsible for regulating cosmetic labeling with the main goal of ensuring consumer safety and avoiding fraudulent and deceptive statements.

What are Cosmetics?

The FDA defines cosmetics as “articles intended to be applied to the human body for cleansing, beautifying, promoting attractiveness, or altering the appearance without affecting the body’s structure or functions.“

Some products that fall under this category include creams, lotions, perfumes, make-up, shampoos, toothpaste, and deodorants.

While it may seem clear what cosmetics are, manufacturers need to be careful when creating, labeling, and marketing their cosmetic products to ensure they fit under the FDA’s definition and regulations.

If not appropriately labeled, some claims may cause a product to fall under the category of a drug, in which case it has to undergo a set of regulations that differ significantly from cosmetics.

Though sometimes lines can be blurred, manufacturers must understand the difference between cosmetics and drugs and label their products accordingly to avoid potential complications, fines, and recalls.

Cosmetic Labeling

Cosmetic products distributed in the United States must comply with all label regulations established by the FDA. Labels are otherwise considered all written, printed, or graphic matter on or accompanying a product.

The FDA requires that all label statements appear on the inside and outside of the packaging and wrapping.

It is also important to note that false and misleading claims and wrongly labeled products that do not follow FDA cosmetic labeling requirements and regulations may be subject to regulatory action.

How to Correctly Label Cosmetics

To ensure the proper placement of cosmetics on the market and that consumers use them appropriately, manufacturers need to take note of adequate labeling requirements and adhere to them as strictly as possible.

A cosmetic label must contain the following:

If you want to learn all about FDA cosmetic labeling requirements and how to meet them with complete ease, read our detailed blog post.

FDA Labeling Requirements for Food

Food labels have very defined rules regarding how they should be placed on packages and containers.

General Food Labeling Requirements

Generally speaking, there are two ways to label food:

No matter the food product, the PDP must display specific information critical for consumers. This includes the food name and the net quantity statement. Food must also include the information panel, which is usually placed to the right of the PDP.

The information panel refers to statements that are generally required to be placed together. They usually include information such as the name and address of the manufacturer, ingredient list, nutrition labeling, and allergy labeling.

It is also important to note that label standardizations must be followed to ensure consistent and easy-to-read labels.

The FDA requires that you use a prominent print size and that the font is clear and legible through specified letter height. Additional formatting is also detailed in FDA guidelines to ensure that text is easy to read on different backgrounds and artwork.

Manufacturers must also ensure that all of their food labels contain the following:

Want to take a deep dive into FDA food labeling requirements? We have the blog post just for you.

How to Meet FDA Labeling Requirements

Regardless of the food, drug, cosmetic, or medical device you want to send out to market, there are constants among them all that help ensure their safety and quality.

Best Practices for Preparing Labels for FDA Review

There are several best practices for preparing labels for FDA review:

The Importance of Label Accuracy

When we look at highly regulated products such as pharmaceuticals, cosmetics, and medical devices, the first thing our eyes go to, is the label. This is where we know we will find all the information needed about that said product.

The information stated on that very piece of content determines whether or not a consumer will find the product suitable and reliable enough to purchase and use. Because of this, the accuracy of labels should be of high priority.

Label accuracy is crucial as it details the products:

In order to have only the highest quality products making it into the hands of consumers, label accuracy should be a top priority throughout the entire product development process. It is important to proof, check, and, review, labels to ensure that they are accurate, complete, and up-to-date.

Common Label Mistakes to Avoid

As inaccurate labels can lead to disastrous consequences for highly regulated industries, proofreading, reviewing, and checking labels should be a thorough and precise process. Mistakes should be avoided by any means necessary.

Some common label mistakes that manufacturers should avoid include:

Best Practices for Maintaining FDA Label Compliance

With many rules, regulations, and requirements to follow, it’s no surprise that such heavy importance is placed on label accuracy. For perspective, in drug labeling, it is estimated that over 50% of medication use errors are associated with poor labels.

Though this includes patient misunderstandings, it is generally believed that implementing standardizations such as text, language, typography, and other display standards will drastically reduce errors in drug labels.

Along with patient safety, it is also important to note that labeling errors lead to significant recalls and financial losses, which are more frequent than one would think.

Clinically important drug recalls occur approximately once per month in the United States. For perspective on just how significant these financial impacts can be, Johnson and Johnson lost roughly $600 million in sales after closing a distribution site due to a recall.

Because of this, best practices should be put in place to ensure that labels are accurate while maintaining manufacturing and distribution efficiency and speed.

One certain method that ensures label accuracy is the implementation of automated quality control, or more precisely, a file comparison tool to check content and labels with complete ease and efficacy.

What is File Comparison Technology?

Content for highly regulated products is produced at such rates and numbers that companies need to turn to technology to help ensure the accuracy of their content and labeling along with all technical documentation.

In other words, file comparison technology is the ideal solution they are looking for.

File comparison technology proofreads documents and files in seconds. The software works by overlaying two files to find discrepancies between the two. No matter how small the errors or differences may be, the software will detect them and pinpoint their exact location on the file.

The software can detect errors in copy and artwork that is nearly impossible to see with the naked eye. Using a document comparison tool, errors and differences can be easily found in text, graphics, barcodes, braille, print, and color.

The result is proofread and error-free labels and packaging in record time – every time.

By introducing file comparison technology to your proofreading and reviewing processes, quality control departments in regulated industries can avoid unnecessary and hasty product mistakes that can be easily corrected and avoided.

The technology gives manufacturers confidence that their products and accompanying labels reach the hands of consumers in pristine condition – down to the last period.

Find out more about how file comparison technology can help quality control teams in regulated industries.

Your New Automated Solution

Many large global corporations in highly regulated industries have yet to implement new technologies that increase workflow efficiency.

In some cases, many still rely on manual and labor-intensive proofreading and reviewing processes prone to mistakes, leaving huge potential for operations to be optimized and streamlined for maximum efficiency.

Automated quality control or a file comparison tool inspects content and artwork with complete ease, lightning speed, and increased accuracy.

To keep up with increasing global consumer demands, regulated industries create an immeasurable amount of products, each with its own packaging, labeling, and documentation. This content must be meticulously reviewed and proofread to ensure that the final product is error-free.

Manually proofreading this amount of content is not an efficient solution for companies that need to keep up with growing demands. File comparison software offers a foolproof solution to ensure all this generated content is checked and proofread perfectly.

This advancement in proofreading processes eliminates the need for manual document inspections and leaves it up to technology. The software conducts digital checks for discrepancies in text, spelling, graphics, color, and more.

The software conducts thorough inspections in a fraction of the time and ensures that labels and content are 100% accurate before going out to the hands of patients and consumers.

This technological advancement ultimately increases productivity and workflow efficiency and offers endless benefits unmatched by manual inspections. Not only does automated proofreading software help ease the proofreading process, it simply makes proofreading better.

Keep Up with FDA Labeling Requirements

If you want to keep up with FDA labeling requirements with complete ease, switch to automated quality control. A trusted technology, GlobalVision’s innovative automated solutions have been solving problems for regulated industries globally for over thirty years.

By using GlobalVision to eliminate time-consuming and inaccurate manual checks, the largest pharma companies worldwide cut review times by 89%. Just by making the simple switch to automated quality control, top companies got critical healthcare products into the hands of consumers faster and with complete confidence that their labels and content are 100% accurate and FDA compliant.

To name only a few, GlobalVision has helped:

Ensuring that you meet all FDA drug labeling requirements is far from easy. Yet, through the simple introduction of automated quality control, companies can rest assured that they are drastically eliminating the risk of human error, getting their product to market faster with fewer revision cycles, and reducing the risk of costly recalls and misprints.

Ready to Automate Your Workflows?

To ensure market success and error-free, perfect labels, regulated industries must streamline their quality control processes. The simple Implementation of file comparison technology helps teams create flawless labels, speeds up the content creation process and revision times, and gets products to market in record time.

The benefits a file comparison tool brings to manufacturers are countless and, in most cases, are a crucial company resource. The only way manufacturers can be completely confident that their content and products are error-free is through fast, accurate, and trusted software such as file comparison technology.

Ready to step into the world of automated proofreading? Request a demo of our innovative text comparison software and see how this technology can revolutionize your everyday business practices. Transform your quality control processes with GlobalVision’s cloud-based quality inspection tool.

Also, to learn more about how technology can help manage regulatory compliance, check out GlobalVision’s guide Digital Transformation for Pharmaceutical Packaging Quality.

———————————————————————————————————————————————————

Related Articles:

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.

How to Ace FDA Food Label Compliance Review: Ensure Your Labels are Always Approved

Date: January, 2023 | Category: Compliance | Author: Hana Trokic

Every food item that makes it to the shelves of grocery stores worldwide undergoes rigorous testing and verification to ensure its safety.

To be precise, it is the responsibility of the Food and Drug Administration (FDA) to assure this guarantee and also to check that all foods are properly labeled and that they follow food label compliance.

This is necessary to give consumers the correct information about the food they buy and consume and to avoid any unnecessary adverse effects that may come with the improper labeling of said products.

From the ingredients list, allergens, date of packaging, and expiry date, all of this information is essential. Yet, more crucial than the information itself is the accuracy of the information on food labels and packaging.

The accuracy of their labels guarantees consumer safety and health, and also allows businesses to avoid recalls and substantial financial losses, while protecting their brand and public image.

In an industry that works in highly regulated and monitored conditions, even the slightest error can lead to enormous consequences. As such, food manufacturers and those working in consumer packaged goods cannot risk faulty labels going out to market.

To ace FDA food label compliance reviews and ensure your labels are always approved, tap into the power of automation. Automated quality control is a comprehensive solution for your compliance needs that ensures all of your food labels meet FDA label compliance review.

Innovative and accurate software proofreads critical content at scale and instantly catches errors to help you get your products to market faster without compromising on quality. You can now rest easy knowing your food labels are completely error-free all the while following FDA food label compliance and passing all reviews and tests.

Food Labeling at a Glance

Food labels have very defined rules regarding how they should be placed on packages and containers.

General Food Labeling Requirements

Generally speaking, there are two ways to label food:

No matter the food product, the PDP must display specific information critical for consumers. This includes the food name and the net quantity statement. Food must also include the information panel, which is usually placed to the right of the PDP.

The information panel refers to statements that are generally required to be placed together. They usually include information such as the name and address of the manufacturer, ingredient list, nutrition labeling, and allergy labeling.

It is also important to note that label standardizations must be followed to ensure consistent and easy-to-read labels. The FDA requires that you use a prominent print size and that the font is clear and legible through specified letter height. Additional formatting is also detailed in FDA guidelines to ensure that text is easy to read on different backgrounds and artwork.

Name of Food

Every food label should be appropriately named so that consumers and the general public know exactly what the product is. The name of the food is referred to as the statement of identity and is required by the FDA to be on the front label.

As packaging for various yet very different food products may look the same, food products must be appropriately labeled to set them apart at first glance.

For a more detailed look at how the FDA breaks down naming food on labels, view their detailed food labeling guide here.

Net Quantity of Contents Statements

The net quantity statement provides information about the amount of food in the container or package. The FDA requires that it be expressed in weight, measure, or numeric count. If the food is solid, the contents are labeled in terms of weight. If it is liquid, they are labeled in fluid measure.

The net quantity statement must be placed at the bottom 30 percent of the PDP and must show net contents in both metric and U.S. Customary System.

Ingredients List

What is a food label without an ingredient list? One of the most crucial aspects of food labels and packaging, the FDA also clearly defines how ingredients should be written and displayed.

Firstly, ingredients are required to be listed in descending order of predominance. In other words, the most prominent ingredient (by weight) is listed first, and so on. The ingredient list is also placed on the same label as the name and address of the manufacturer.

Like other FDA food label rulings and regulations, the ingredients list is subject to strict standardization. Font and typography should be prominent and unified following the instructions given by the FDA, and the list should always be straightforward and easy to read.

Food Allergen Labeling

Under FDA label compliance, food labels are required to include all ingredients that are major allergens and can cause allergic reactions and potential harm to consumers.

While more than 160 foods have been shown to cause allergies to those with food sensitivities, only eight “major food allergens” must be labeled. This is because these ingredients, or an ingredient that contains protein derived from them, account for 90 percent of all food allergies.

The eight major food allergens include:

Nutrition Labeling

The nutrition label provides crucial information to consumers about the nutritional value of the product, broken down by calories, carbs, fat, fiber, protein, and vitamins per serving. It’s easily identifiable as the tabular, square, or rectangular-shaped information panel on all food products and packaging.

This label is usually displayed with the ingredient list and the name and address of the manufacturer. The location of the nutrition label is not precisely defined by the FDA and can be placed on packaging panels that can be clearly found and seen by consumers.

The FDA goes into great detail about nutrition labeling to ensure accurate information is being given and displayed to consumers.

For full details about FDA label compliance for nutrition labeling, see how the FDA breaks down this aspect of food labeling in their detailed guide.

Nutrition Content Claims

Nutrition content claims are claims made on food labels and packaging that imply certain nutrient characteristics of the food. This includes claims such as “low fat,” “high in protein,” and “only 100 calories per snack.”

We’ve all seen these claims on many food products and probably have several in our kitchen at any given moment. These claims aim to describe the level of certain nutrients in a specific food product.

They usually include words like free, high, low, reduced, lite, etc. The claims and labels are also regulated by the FDA but usually only apply to those with an established daily value.

Ace FDA Food Label Compliance Review Through Automation

Suppose a typo or even a tiny error was to slip through. In that case, food manufacturers could face immense consequences, including large recalls, financial losses, and a negative brand image that could be difficult to reverse. The downfalls that come with faulty food labeling are often irreversible.

To save your company from going through horrific scenarios and prevent detrimental errors, food manufacturers should turn to automation as a foolproof solution to all proofreading needs.

Automated quality control makes proofreading processes more efficient and drastically eliminates the risk of errors slipping through in critical and highly regulated content.

In essence, automated quality control in proofreading is a file comparison tool that overlaps two files to find the discrepancies between them. No matter how minor the differences may be, the software will detect them, pinpoint their exact locations, and generate a comprehensive inspection report allowing users to review and navigate through all found differences.

A simple yet highly effective solution, all that is required from quality control teams is to upload both documents, conduct a scan, and view the discrepancies in the generated report.

By using automated solutions for their proofreading needs, food manufacturers can rest assured that their highly critical content is verified with 100 percent accuracy, in record time, and with absolutely no need for manual checks.

More than Just Text Inspection

While proofreading is often thought to be just for text, file comparison technology allows you to check, review, and inspect files wholistically. As food labels include different elements such as various fonts, typographies, graphics, and artwork, manufacturers can scan complete files in one go without having to do multiple inspections or reviews.

A file comparison tool can detect errors in the following:

Whatever discrepancies may appear in various revision cycles, they will all be detected within seconds to ensure a flawless master copy. GlobalVision’s file comparison software scans and inspects all files to find even the most minor errors allowing you to publish accurate and pixel-perfect labels.

Perfect Labels, Every Time.

Critical content in highly regulated industries should undergo rigorous and detailed reviews, but that doesn’t mean they have to be complicated and time-consuming. Automated quality control allows for thorough inspections that increase efficiency while decreasing review times and errors.

Food manufacturers can expect to experience countless benefits and advantages by implementing automated quality control – a leading proofreading solution for all regulated industries. An easy fix that ensures that all of your labels meet FDA food label compliance reviews, automated quality control is a comprehensive solution that does it all.

Enhance your proofreading practices and make the switch today. See how automated quality control can streamline your revision workflows by allowing you to proofread critical content at scale while maintaining complete accuracy.

Discover firsthand the benefits of automated quality control. Request a demo of GlobalVision, and get started today!

———————————————————————————————————————————————————

Related Articles:

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.

Overcome Your Content Challenges in Cosmetic Labeling to Meet FDA Requirements

Date: December, 2022 | Category: Proofreading | Author: Hana Trokic

When most of us go out searching for our next “new favorite product,” we rely heavily on the claims written on the packaging. “All natural ingredients,” “results after only one use,” and “98% effective” are only some claims we see scattered across cosmetic aisles globally.

But just how effective are these labels? For perspective, ask yourself, would you buy a cosmetic product that didn’t have a label? What about a product that had errors and typos on its labeling? It’s safe to say that most of us would skip that product and move on to one with more enticing branding and trustworthy labeling and packaging.

In other words, packaging and labels are consumers’ first impressions of your product, so you want to get it right. As a form of advertising, cosmetic labels often include a long list of promises as manufacturers try to sell you on their claims. Yet, not only do they have to convince you of their guarantees of beauty and benefits, but they also need to sell you on its efficacy.

Moreover, cosmetic manufacturers operate in a highly regulated industry, further complicating the labeling process. Not only do they have to consider branding and marketing guidelines, but they also have to focus on FDA cosmetic labeling requirements, as there are strict rules and regulations behind every cosmetic label.

The Challenges of Cosmetic Labeling

All cosmetics marketed globally must comply with provisions set by the governing body of that specific country or region. In the United States, the FDA is responsible for regulating cosmetic labeling with the main goal of ensuring consumer safety and avoiding fraudulent and deceptive statements.

What are Cosmetics?

The FDA defines cosmetics as “articles intended to be applied to the human body for cleansing, beautifying, promoting attractiveness, or altering the appearance without affecting the body’s structure or functions.“

Some products that fall under this category include creams, lotions, perfumes, make-up, shampoos, toothpaste, and deodorants.

While it may seem clear what cosmetics are, manufacturers need to be careful when creating, labeling and marketing their cosmetic products to ensure they fit under the FDA’s definition and regulations. If not appropriately labeled, some claims may cause a product to fall under the category of a drug, in which case it has to undergo a set of regulations that differ significantly from cosmetics.

Though sometimes lines can be blurred, manufacturers must understand the difference between cosmetics and drugs and label their products properly to avoid potential complications, fines, and recalls.

Cosmetic Labeling

Cosmetic products distributed in the United States must comply with all label regulations established by the FDA. Labels are otherwise considered all written, printed, or graphic matter on or accompanying a product.

The FDA requires that all label statements appear on the inside and outside of the packaging and wrapping.

It is also important to note that false and misleading claims and wrongly labeled products that do not follow FDA cosmetic labeling requirements and regulations may be subject to regulatory action.

How to Correctly Label Cosmetics

To ensure the proper placement of cosmetics on the market and that consumers use them appropriately, manufacturers need to take note of adequate labeling requirements and adhere to them as strictly as possible.

A cosmetic label must contain the following:

Product Identity

Product identity is the most crucial aspect of FDA cosmetics labeling requirements as it tells consumers what your product is and its intended use. Many cosmetic products and packaging look the same, i.e., lotions, shampoos, creams, etc.

The label and statement of identity are what help consumers tell them apart. Because of this, product identity has to be displayed on the front of the package, so the general public is immediately aware of its intended use.

Net Contents

Net contents tell consumers the quantity of your product, i.e., how much product is in the package.

Products that are solids display their net content in terms of weight, while liquid products display their contents in terms of volume. The accuracy of the net contents is also highly regulated by the FDA as it ensures that it accurately reveals the quantity of cosmetics in the container in terms of weight, volume, measure, numerical count, or combinations of count and weight, volume, or measure.

Declaration of Ingredients

All cosmetics under the FDA are required to bear an ingredient declaration.

The declaration of ingredients must be clearly visible so that it can be found and read at the time of purchase. The placement of the ingredients is not strictly standardized like the product name or net contents. It can be displayed on any information panel on the package.

The ingredients must also be listed in order of predominance. In other words, the ingredient with the highest percentage is listed first, while other ingredients are listed according to their percentage in descending order. Ingredients at 1% or less can be listed in no particular order at the end of the ingredient declaration.

Label Warnings

Cosmetics that may cause adverse reactions or be hazardous to consumers if improperly used must be addressed through FDA cosmetic labeling requirements. Appropriate warnings and directions of use need to be clearly labeled and prominently displayed.

Some cosmetics that fall into this category include:

Overcoming the Cosmetic Labeling Challenges

Just as it’s crucial to follow FDA regulations for labels, it’s equally as important that those labels are entirely error-free. Typos and artwork errors can make cosmetic products seem untrustworthy and unreliable. After all, why would consumers trust the contents of a product that was so hastily packaged and labeled?

Once you have ensured your labels meet all FDA cosmetic labeling requirements, the next step is to ensure that your content and artwork are error-free.

Text comparison software is a tool that allows cosmetic manufacturers to run an automated side-by-side comparison of two files to identify discrepancies and errors with complete ease.

Eliminating the need for laborious and error-prone manual proofreading checks, this advancement in automated quality control simplifies, optimizes, and upgrades workflows to ensure that your cosmetic labels are always top quality and free from mistakes.

Through the simple addition of this software, manufacturers can proofread and run checks for every aspect of their labels and packaging. With accuracy and precision, the software finds errors and discrepancies in text, colour, graphics, barcodes, and print, to name a few.

To ensure that you keep your product’s quality, reliability, and status on the market, implement processes that keep your labels and packaging safe from unwanted errors.

Automated quality control streamlines revision and proofreading processes and brings endless benefits for businesses and manufacturers – especially those dealing with sensitive copy, documentation, and content, such as pharmaceuticals and cosmetic manufacturers.

Cosmetic Labels that Meet all FDA Requirements

A miracle in a bottle – a claim most cosmetic manufacturers love to make. Yet without proper labeling and packaging, it’s hard for them to make such a statement and sell consumers their product.

To ensure market success and picture-perfect labels that stand out, you must get your cosmetic labels right. Implement a text comparison tool that helps you create flawless labels, speeds up the content creation process and revision times, and gets your product to market in record time.

The benefits a file comparison tool will bring cosmetic manufacturers are countless and, in most cases, are a crucial company resource. The only way manufacturers can be completely confident that their content and products are error-free is through fast, accurate, and trusted software.

Ready to step into the world of automated proofreading? Request a demo of our innovative text comparison software and see how this technology can revolutionize your everyday business practices. Transform your quality control processes with GlobalVision.

Also, to learn more about how technology can help manage regulatory compliance, check out GlobalVision’s guide Digital Transformation for Pharmaceutical Packaging Quality.

Related Articles:

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.

How to Ease the Labeling Proofreading Process for Medical Devices

Date: November, 2022 | Category: Proofreading | Author: Hana Trokic

A medical device can range from the simplest household item found in everyone’s pantry, like a band-aid, to more complex technology like an x-ray machine. Regardless of its complexity, there is a constant amongst them all. They all need to be tested and approved to meet FDA requirements and compliance.

While there is a long list of requirements to meet to even be classified as a medical device by the FDA, once labeled, there are strict rules and regulations put in place to ensure its proper use along with patient and consumer safety. These rules surround all documentation associated with the device, including labels, packaging, and technical documentation.

A long and tedious process, FDA labeling requirements for medical devices is rigorous for good reason. The detrimental consequences that can come with the improper use of devices are extremely high risk and companies make sure to take every precaution possible to avoid irreversible and potentially permanent problems.

One way medical companies ensure the safety and quality of their products is through precise checks, reviews, and thorough proofreading. Every aspect of the device is inspected and reviewed to ensure no mistakes have slipped through and that the final product is error-free.

Yet, when companies rely on manual methods as their primary approach to proofreading and quality control, they are increasing their chances of producing faulty products, labels, and packaging, due to the heightened likelihood of human error.

Luckily, pharmaceutical companies and medical device manufacturers don’t have to rely on manual methods anymore to ensure their label and content accuracy. They can now turn to automated quality control as their secret to flawless labels, artwork, and products.

Types of Medical Devices and Their Regulations

Medical devices can range from simple to complex. Regulatory authorities globally have put into place risk classifications that group devices into categories based on their potential harm if misused, the complexity of the device, and certain use characteristics.

These classifications are essential to ensure safety and ease the marketing and placement of devices. It also sets a standard for testing where officials know, according to classification, how much testing a device needs to undergo to be deemed safe and ready for patient use.

Medical Device Classification

In the United States, the FDA has classified medical devices into three categories based on the level of control needed to ensure the safety of use. The classifications are:

Regulations and Standardizations

Regardless of their classification, it’s important that all medical devices adhere to a certain set of regulations and standardizations. Much like pharmaceuticals, medical devices are treated with similar rigor and are highly regulated.

The FDA offers a detailed overview of all the regulations devices need to follow in order to be deemed fit for use by the general public. The International Organization for Standardization (ISO) sets the standards and convenes them for ease of implementation in the industry.

Some regulations that are put in place for medical devices include:

Labels and Labeling

The FDA defines a label as a “display of written, printed, or graphic matter upon the immediate container of any article” or “all labels and other written, printed, or graphic matter.”

As such, labels are the first point of contact for information for many medical practitioners, patients, and consumers, and need to be accurate to avoid confusion or life-threatening consequences.

The FDA breaks down label regulations and clearly defines them by the following:

These regulations are in place to primarily ensure that the products and devices in question are being used as they are intended and that the safety of those using them is guaranteed.

Keeping up with these regulations is already an extremely complicated process, but simplifying workflows and streamlining processes to increase efficiency is very much possible.

Once you ensure that your medical device labelings are following all regulations and standardizations how can you ensure that the written, printed, and graphic matter of your products are error-free?

A document comparison tool is the natural next step in your regulation and standardization process that enhances your labels and artwork and makes keeping up with regulations easy. In a fraction of the time, you will be able to check and inspect entire files and documents and increase the accuracy of labels while easing the FDA labeling requirements put in place for medical devices.

Making FDA Labeling Requirements a Breeze

While traditionally manual checks were the method by which medical device labels, packaging, and graphics, were inspected, in today’s modern, globalized markets, demand is too large to rely on outdated methodologies.

Devices and accompanying content are being produced at such rates and numbers that companies need to turn to technology to help ensure the accuracy of their products along with all technical documentation.

In other words, a text comparison tool is the ideal solution they are looking for.

A text comparison tool proofreads documents and files in seconds. The software works by overlaying two files to find discrepancies between the two. No matter how small the errors or differences may be, the software will detect them and pinpoint their exact location on the file.

The software can detect errors in copy and artwork that is nearly impossible to see with the naked eye. Using a document comparison tool, errors and differences can be easily found in text, graphics, barcodes, braille, print, and color.

The result is proofread and error-free labels and packaging in record time – every time.

To avoid unnecessary and hasty product mistakes that can be easily corrected and avoided, introduce text comparison technology to your workflows to ensure your medical device labelings reach the hands of consumers in pristine condition – down to the last period.

Ready to Simplify Your Processes?

In an already complicated and highly regulated industry, keeping up with regulations can be complicated and hard to follow.

Pharmaceutical companies and medical device manufacturers should search for solutions to help ease the FDA labeling requirements for medical devices while simultaneously increasing the accuracy of their labels and the efficiency of creating and printing them.

Through the use of the right technology, such as text comparison technology, companies and manufacturers can see increased benefits in their workflows that result in better and more accurate products.

Using trusted automated proofreading technology like GlobalVision, companies in regulated industries can automate their quality control and get products to market faster, with complete confidence.

To learn more about file comparison technology and how it can benefit your company, request a demo of GlobalVision today!

Related Articles:

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.

Ensure Your Labels Meet all FDA Drug Labeling Requirements with Automated Quality Control

Date: November, 2022 | Category: Quality | Author: Hana Trokic

For highly regulated industries like pharmaceuticals, following FDA drug labeling requirements is one of the most crucial aspects of the product lifecycle. With so many laws, rules, and regulations to follow, the task of creating documentation, labels, and content surrounding a single drug or product quickly becomes stressful and tedious.

Yet, drug label requirements are in place for a reason – and a good one at that. The accuracy of drug labels ensures that patients and consumers are being given proper instructions and dosages of a prescribed drug. Label accuracy also ensures that pharmaceutical companies avoid life-threatening side effects for their consumers, large recalls, and colossal financial downfalls.

With so much on the line, pharmaceutical companies cannot risk label errors slipping through.

Thankfully, software shortcuts such as automated quality control is a one-stop shop for your compliance needs that makes sure your labels meet any and all FDA drug labeling requirements.

Automated quality control is an easy solution that allows you to proofread labels and content in record time. Not only does it decrease proofreading and review times, but it also decreases errors while increasing the efficiency of your workflows.

With this comprehensive software solution, you can ensure that all of your labels follow FDA requirements while being accurate and completely error-free.

The Highly Regulated Pharmaceutical Industry

When it comes to drug labeling, the FDA’s primary purpose and concern are to ensure patient safety and provide healthcare professionals with information about the drug and how it should be prescribed. Some of the FDA’s drug label requirements include:

With so many regulations to follow, it’s no surprise that such heavy importance is placed on label accuracy. Even so, it is estimated that over 50% of medication use errors are associated with poor drug labeling. Though this includes patient misunderstandings, it is generally believed that implementing standardizations such as text, language, typography, and other display standards will drastically reduce errors in drug labels.

Along with patient safety, it is also important to note that labeling errors lead to significant recalls and financial losses, which are more frequent than you would think. Clinically important drug recalls occur approximately once per month in the United States. For perspective on just how significant these financial impacts can be, Johnson and Johnson lost roughly $600 million in sales after closing a distribution site due to a recall.

To avoid the detrimental consequences that label errors bring, pharmaceutical companies need to implement a functioning proofreading and reviewing process. They must inspect labels, artwork, and content at every step of production, ensuring the accuracy of the complete file.