How do You Inspect Packaging of Bottles, Cans and Cylinders

Date: April, 2016 | Category: Proofreading | Author: Reuben Malz

Packaging and labeling are driven by a number of factors. First, you have the ergonomics of the package, ensuring that the object is packaged properly ensuring protection, convenience, and the proper message is communicated.

Another key factor is its market appeal, the artwork, colors, and fonts that companies use directly influence sales. There is truly a science behind it. However, it is important to ensure that there are no errors because no matter how nice the package is, consumers will not buy goods that are mislabeled.

An error in labeling is the number one reason why products are recalled. Companies have paid millions of dollars in fines and penalties to recall products for simple product mislabeling; in fact, the average cost of a product recall is between 5 – 10 million dollars. Finally, the damage to a company’s reputation can be immeasurable and could amount to a company failing.

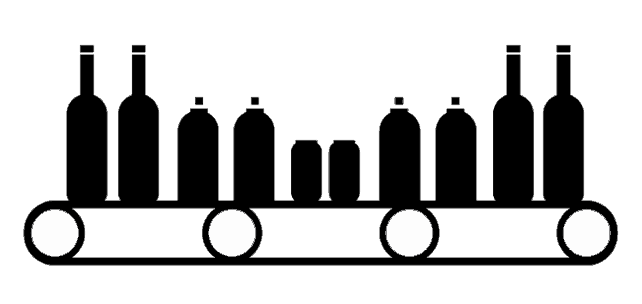

Inspecting Labels on Bottles, Cans, and Cylinders

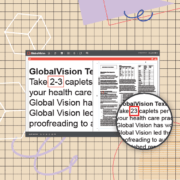

To ensure the package is error-free, progressive companies now use automated proofreading solutions throughout the design and printing of the package and label. In fact, for every phase of the packaging workflow, a different proofreading solution can be used for inspection purposes anywhere from text and artwork inspection to barcode and braille verification.

To inspect a printer proof versus the approved artwork is a relatively straightforward job and done by most printers before completing the entire press- run. A sample of the printed piece is first scanned with a Roll or Flatbed scanner and then uploaded into a print inspection solution like the print inspection tool by GlobalVision. Packaging that can be laid flat, such as labels and folding cartons, poses little problem. However, until recently, packaging that is cylindrical poses a unique challenge to printers and their customers.

In the past, companies would cut cylindrical containers such as cans and tubes, try to get it flat as possible, and lay them on a flatbed scanner. This posed a few critical problems, the first being that you can never really get the sample container flat enough. Secondly, it is very time-consuming and can be a little dangerous. Also, you can severely damage or at a minimum shorten the scanner’s life.

Greater Inspection Accuracy with GlobalVision:

GlobalVision’s innovative automated proofreading software has been the leading developer of cylindrical inspection solutions for over two decades. The comprehensive quality control solution has the ability to inspect packaging and labels of the following:

- Large heavy-gauge metal cans

- Ribbed cans

- Embossed text

- Rough textured plastic finishes

- Shrink-wrapped cylindrical items

- Aluminum cans

- Glass jars

- Plastic bottles

- Soft metallic containers

- Polymer tubes

- Cylinders

With so many regulations affecting pharmaceutical and CPG companies, the need to ensure packaging accuracy has never been greater. With GlobalVision, even printed cylindrical items can be effectively and rapidly inspected, safeguarding against errors, reprints product recalls, and the accompanying financial loss.

If you want to begin streamlining your label and packaging inspection processes, request a free trial today for GlobalVision’s Print Inspection Solutions

Also, learn more about the pressing need to scan cylinder packaging.