Date: November, 2023 | Category: Quality | Author: Hana Trokic

While “going green” may be a proud point for many businesses in this day and age, in the world of packaging and design, it’s not necessarily going far enough. Instead, it’s all about being sustainable.

However, true sustainability doesn’t just take into account the materials that go into packaging. True sustainability also considers potential waste during the production process. When introducing end-to-end sustainability, businesses need to look back to the very beginning, to the point where the packaging is designed and then approved.

It is important to note that the packaging approval process can result in many rounds of revisions until everything is ready for production. The result can create wasted resources if your process isn’t as tight as possible, even if the packaging itself is 100% sustainable.

As a result, significant resources get wasted when mistakes slip through your supply-chain cracks. Avoidable errors can result in recalls leading to heaps of wasted packaging that have no value. For perspective, in 2015 alone, 77.9 million tons of municipal solid waste generated in the United States consisted of containers and packaging. Over one-third of that total ended up in landfills.

Read on to discover how to create truly sustainable packaging and processes for your business.

What Is Sustainable Packaging?

While a product that’s labeled as “green” carries a positive, eco-friendly connotation, it’s vague by standards set by the Federal Trade Commission.

For example, “green” generally means one or some combination of the following:

- Compostable

- Degradable

- Non-toxic

- Ozone-safe/ friendly

- Recyclable

- Made from recycled content

- Made with renewable energy

- Made with renewable materials

- Refillable

“Green” may sound satisfactory, but each of the above actually conveys something tangible. According to Diana Fryc, Director of Operation of Retail Voodoo, using compostable packaging is just one step.

“Aside from compostable packaging, there is still a strong desire to reduce the size of packages, continued desire to use fewer adhesives, and continued use of the post-consumer recycled material,” she says. “Lighter materials to save on shipping costs and form factors that maximize shelf space bottles will also continue.”

In fact, packaging that’s “sustainable” is understood to meet a long list of specific criteria, featuring many of those same characteristics. To further illustrate this point, the Sustainable Packaging Coalition has developed its own criteria for what defines sustainable packaging:

- Sourced from materials that each remain healthy throughout the lifecycle

- Manufactured using clean technologies and best practices, to optimize materials and energy, thereby meeting/exceeding competitive performance and cost standards

- Transported efficiently via fossil fuel alternatives, helping to develop renewable energy markets

- Recycled, recovered, and utilized in closed biological/ industrial loop cycles

Of course, the International Organization for Standardization (ISO), the Consumer Goods Forum, and CEN all have alternative packaging standards. So, globally speaking, there aren’t any hard, fast rules for what constitutes sustainable packaging. There are, however, certain guidelines.

Following them is far from easy, but this guide will help you understand the basics as you maneuver through the complex world of sustainable packaging and its implementation.

Reducing Your Carbon Footprint

Ultimately, by introducing sustainable packaging into your supply chain, businesses are aiming to reduce their carbon footprint as a whole. This includes securing product packaging workflow through effective quality control.

Preventing recalls by catching errors means less packaging, less waste, and therefore, a lot less energy consumed. After all, the resources needed to carry out recalls, which cost on average $10 million in the food industry, don’t include the transportation and labor costs of putting more packaging through your supply chain and re-shipping the product. It all affects your bottom line and the packaging footprint you’re trying to market as sustainable.

Therefore, it’s time to start looking beyond the product and at the complete end-to-end process. Many companies are integrating new technologies and automated systems that can spot errors before going to print as a pre-emptive strike against recalls. The main goal is to address sustainability, as it’s important to consider how products are made and how to be as efficient as possible with the resources available.

It turns out the idea that integrating sustainable packaging leads to higher costs is actually a myth. Studies show that companies that look to become more eco-friendly overall enjoy as much as an 18% return on investment increase. That’s potentially a lot of green for going green.

Have you heard about footprint packaging? Learn more by reading our detailed blog post.

The Need for Sustainable Packaging

There’s little denying the benefits of sustainable packaging. There are financial benefits in store for any corporation moving in that direction. That’s not just due to the increased back-end efficiency and economies of scale that result from such a move.

If marketed correctly, sustainably packaged products have been proven likely to sell more.

Obviously, a company shouldn’t make the switch simply to appease its conscience. All things being equal, it just makes sense to waste less and promote a brighter future filled with less waste.

“Packaging is a polluting factor” says Andreas Kioroglou, the CEO of Matador Design. “Creative design will [start to] take into account factors like the reduction of the carbon footprint of packaged goods throughout the supply chain and designs that will extend the packaging life cycle.”

Read what more experts are saying about sustainable packaging here.

Over the long term, it is expected that sustainable packaging solutions will lead to higher profits relative to one’s current process. The only thing holding companies back is the inevitable, albeit short, discomfort that results from transitioning to a new and improved process.

Implementing Sustainable Packaging

Packaging plays a crucial role in influencing customers’ buying behavior, yet unsustainable packaging can damage the reputation of a company, causing customers to switch to other brands that employ environment-friendly materials and processes.

Unsustainable packaging is detrimental to the environment as it increases the amount of waste that is diverted to landfills, causing increased greenhouse gas emissions.

Sustainable packaging can reduce our ecological footprint at all stages of the product life-cycle, helping the manufacturer and the customer work towards a sustainable future.

With sustainability being the major agenda for almost all countries around the globe, several organizations are introducing sustainable packaging in order to reduce the negative impact on the environment and differentiate themselves from the competition.

However, the industry is not devoid of misconceptions that could cause confusion, making it challenging for organizations to work toward a sustainable future.

Sustainable Packaging Is An Added Cost

It is a common belief that a majority of product improvements come with a high price tag. Though the cost of sustainable packaging may seem to be high initially, it offers numerous benefits that contribute to the long-term success of a business. Moreover, socially responsible businesses incorporate the extra cost of sustainable packaging as a part of their business plan, assuring them of profits in the long term.

Adopting sustainable or green packaging enables marketers to connect with their eco-conscious and green-aware consumers, giving them a competitive advantage and boosting profits. In fact, studies conducted by the Carbon Disclosure Project (CDP) prove that organizations that adopt eco-friendly materials and processes are likely to see a return on investment of 18 percent or more.

Apart from attracting new customers and boosting your corporate image as an environmentally-responsible organization, sustainable packaging also offers innovative designs that can be tailored to the clients’ specific requirements.

For instance, waste can be recycled using the paper molding process and converted into customized packaging in order to meet the firm’s requirements for heavy and delicate products at an extremely affordable rate. All this eliminates excessive packaging, making the shipments light and drastically reducing the products’ footprints on the store shelves.

Additionally, in recent times, brands cannot afford to ignore eco-friendly strategies. Consumers increasingly prefer products that protect the environment, reduce global warming, and prevent air and water pollution.

Consequently, both emerging and advanced markets are drifting towards ethical and environment-friendly options, pushing designers, marketers, and package development experts to meet the right social and environmental standards.

Most countries also offer special subsidies and incentives for businesses that are looking to join the sustainability bandwagon. Moreover, firms going the sustainable way also enjoy preferential terms and tax rebates from the state and local authorities for setting up an environment-friendly business.

Thus, green packaging actually stands to save money by reducing material and shipping costs and minimizing waste, playing a persuasive role in helping customers choose your brand over the competition.

Sustainable Packaging Choices are Limited

With the growing concern regarding waste being diverted to landfills and the ensuing greenhouse emissions, customers are expecting firms to use eco-friendly elements in their products.

Consequently, packaging firms have come up with several innovative and green materials, namely polylactic acid (PLA), bagasse, recycled paper, and post-consumer polystyrene that can be used to manufacture coffee cups, plates, cutlery, and boxes.

For instance, Evocative, a New York-based biomaterials firm developed a mushroom-based material that can be used as an alternative to plastic packaging. Similarly, Biopac, a UK-based bioplastic developer uses polylactic acid (PLA) from renewable plant sources to manufacture compostable cups and food packaging.

Sustainable Packaging Adds to Waste

Sustainable packaging is not merely about the eco-friendly nature of the final product. Instead, it means that the packaging material is made from biodegradable, reusable, and environmentally-safe matter and uses energy-efficient manufacturing procedures and health-friendly working conditions for the staff involved.

Sustainable packaging helps firms streamline the packaging design, eliminating unnecessary material from the processes and creating less packaging-related waste. Materials such as biodegradable plastics, plant-based plastics, and recycled products are used to develop sustainable packaging, making it possible for manufacturers and consumers to reduce the amount of waste being diverted to landfills and the ocean floor.

For instance, molded fiber products, namely egg trays, fruit-and-vegetable trays, compostable plant holders, and wine shippers are made using biodegradable waste procured from recycling companies and individual households.

Sustainable Packaging is Unappealing to Consumers

Most commonly, when people think of sustainable packaging they envisage a dull brown or cream paper with visible reused fibers. However, technology has made it possible for design firms to come up with innovative packaging that harnesses powerful aesthetics and is environment-friendly at the same time.

Many international brands and powerhouses such as Samsung, Zara, and Puma offer attractive packaging yet use 100 percent eco-friendly material, preserving the planet and its natural resources.

Want to learn more about sustainable packaging myths? Click here to read our in-depth blog post.

Transitioning to Sustainable Packaging

While some companies are already fully onboard the sustainable packaging bandwagon, others are either on route to making the transition or have yet to make a firm decision on the matter.

For the companies already in existence, it’s about altering the course. Once you’ve committed to making the leap, it’s important to determine your ultimate goals. While the Sustainable Packaging Coalition’s criteria favor a circular economy (or closed loop, which relies on renewable energy), it’s by no means the only choice.

Another is to develop packaging with a linear lifecycle. There, packaging ultimately ends up as trash instead of biologically degrading. It can also be considered eco-efficient, depending on other production factors. It also means bigger short-term gains. The closed loop means more risk and long-term investment, but a higher potential payoff through legitimately sustainable packaging.

Here are some tips to help execute a proper sustainability strategy:

- Get buy-in: Empower employees to take charge and get more emotionally invested in the outcome of the change in strategy. Businesses can also get buy-in from the public. Communicate the change in your corporate philosophy. Done right, it can only improve your image as a forward-thinking company.

- Choose the right materials: It goes beyond selecting materials that are recyclable or even materials that are renewable. While renewable feedstocks are one sustainable direction in which to go, there are other things to consider. For example, how their functionality compares to that of traditional materials. “Sustainable” is great, but it means little if the packaging doesn’t do what it needs to.

- Get to designing: It will be a long process, but thoroughly evaluating each required packaging component will go a long way toward ensuring an overall sustainable design. Simple ones, made from single materials without secondary and tertiary packaging, are easily disassembled and recyclable. That also means minimal glue when possible. Creating packaging that is reusable and multi-functional also wins market points from a sustainability perspective and with consumers.

- Invest in quality control: Quality control processes are critical, especially when rolling out dramatically different packaging that can contribute to product spoilage. Automating quality control and eliminating proofing fatigue, human error, and errors in general, can also contribute to long-term sustainability.

Automation to Sustainability

Automated quality control tools are indispensable assets for businesses striving to enhance their sustainable packaging processes. These tools, driven by cutting-edge technology offer multifaceted advantages that extend far beyond mere error correction.

In the context of sustainable packaging, precision is paramount. This software meticulously scans through all packaging-related content, including labels, product descriptions, usage instructions, and promotional materials, ensuring that they are free from spelling, grammar, and formatting errors. By maintaining a high standard of accuracy, businesses reduce the likelihood of recalls, reprints, and costly product corrections, directly contributing to a more efficient and eco-friendly production process.

By preventing errors, reducing rework, and promoting sustainability, automated proofreading software helps minimize waste in the production process and optimize resource utilization. They aid in curbing the overuse of materials and energy while contributing to the reduction of the carbon footprint associated with packaging.

In the eyes of environmentally-conscious consumers, these efforts resonate as a genuine commitment to sustainability, ultimately enhancing a company’s brand reputation and its competitiveness in the market.

Automated quality control is not just about catching typos; it’s a vital enabler in a business’s journey toward sustainable packaging. The software streamlines operations, reduces costs, encourages green thinking, and helps businesses establish themselves as responsible actors in environmental protection and sustainability.

As sustainable packaging gains increasing importance in today’s eco-conscious world, this technological solution is becoming an indispensable instrument for companies committed to both excellence and environmental consciousness.

A Sustainable Future

The global packaging and protective packaging market was valued at $1.0 trillion in 2021, and is projected to reach $1.5 trillion by 2031, which would result from steady year-over-year growth.

Innovation will logically end up being one driver of that valuation, just as it is currently in the manufactured goods sectors directly reliant on it. That’s simply the nature of a free-market economy in which consumers reward the cutting-edge.

As a result, it’s no longer a matter of going green. It’s arguably not even about going sustainable. It’s about striving to reach sustainability. As the exact definition of “sustainable” is a fast and moving target, it’s more a matter of taking steps towards attaining that goal.

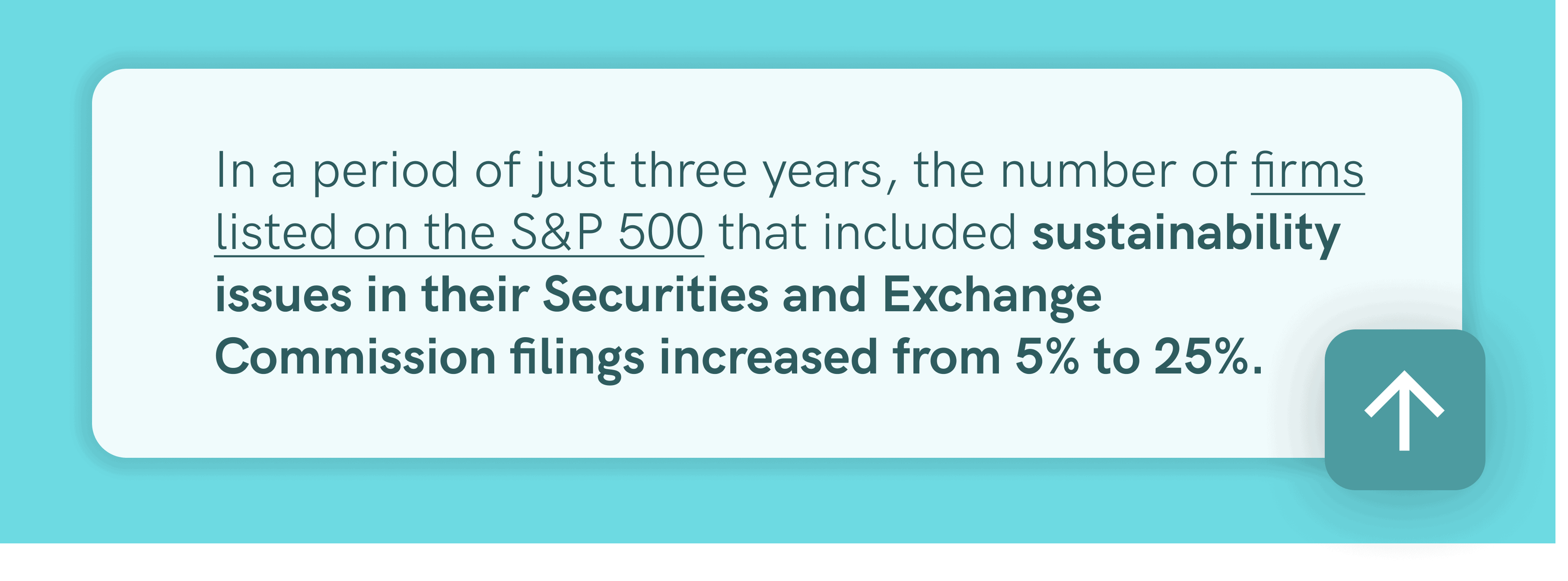

In a period of just three years, the number of firms listed on the S&P 500 that included sustainability issues in their Securities and Exchange Commission filings increased from 5% to 25%. That in and of itself may not be a testament to how successful sustainability can be, but it is of how the times are becoming more eco-friendly.

Joining in on the success means changing with the times, or, perhaps more accurately, adapting. Both customers and the companies behind the products they consume stand to benefit from the large-scale evolution of packaging, which is taking place right before our eyes.

If you would like to take a step into implementing sustainable packaging into your business, start by implementing smart, technological solutions that can easily help you get there. Automated quality control is a comprehensive solution that will not only streamline your proofreading and quality assurance processes, it will also help your business achieve true sustainability with far greater ease.

Request a demo of our innovative proofreading software and see how this technology can revolutionize your every day, sustainable business practices.

Verify’s New AI-Powered OCR Feature Brings Unmatched Character-for-Character Inspections to Regulated Industries

Date: February, 2024 | Category: Company | Author: Hana Trokic

Verify’s New AI-Powered OCR Feature is Here!

Verify, GlobalVision’s newest and most innovative cloud-based proofreading software, has just raised the bar for proofreading in regulated industries with the official launch of its groundbreaking AI-powered OCR (optical character recognition) feature.

This launch is set to transform the compliance and proofreading landscape, bringing with it many benefits that cater to the diverse needs of regulated industries ranging from regulatory, commercial pharma, to agencies, labeling and more.

The addition of OCR to the Verify platform marks a strategic launch into Artificial Intelligence, aligning with GlobalVision’s commitment to empowering regulated industries with cutting-edge solutions that facilitate their workflows and accelerate time-to-market.

Watch our OCR feature in action!

The OCR Technology Gap

Previously, without OCR proofreading technology, regulatory, commercial, and labeling professionals in regulated industries, as well as the agencies that serve them, struggled with manual processes, facing challenges in handling flattened documents containing rasterized text. They were forced to perform visual text extractions, manual proofreading, and manual data entries.

While receiving flattened documents is often out of their control due to the many stakeholders often involved in working on a single document, in the absence of OCR technology, having to perform manual proofreading hinders efficiency, exposes them to potential errors and compliance risks, compromises consumer and patient safety, and causes bottlenecks in the asset development process.

These critical problems only worsen with the added challenge of localization and translation tasks necessary for scalable, multinational operations.

Verify’s AI-Powered optical character recognition technology is designed to solve these problems and revolutionize how regulatory, commercial, agencies, and labeling teams handle text within their document review processes, bringing automation and accuracy to the forefront.

OCR for Compliance With Regulatory Requirements

For industries governed by strict regulations, compliance is non-negotiable.

Regulatory teams are often faced with the difficulty of dealing with rasterized documents, leading to manual inspections, increased risk of errors, and workflow inefficiencies. Similarly, commercial teams and agencies encounter difficulties in handling vast amounts of promotional content which is held to the highest standard in compliance, hindering creativity and time spent on more meaningful work. In parallel, labeling teams also deal with proofreading tasks within strict deadlines and regulations.

With the launch of Verify’s newest AI-powered OCR feature, compliance and review processes are simplified through the automation of text extractions, and the verification of critical text data in documents. This not only eliminates the need for error-prone manual checks, it ensures greater accuracy and significantly reduces the risk of human error, ultimately streamlining compliance processes and ensuring compliance with global health authorities.

Regulated companies can now navigate the complex regulatory landscape with greater confidence, knowing that Verify’s OCR feature acts as an added layer of insurance, guaranteeing the quality of their documentation.

Increased Patient and Consumer Safety Assurance

Verify’s OCR feature will help ensure the accuracy of critical content that is directly associated with patient and consumer safety. This spans a wide range of content types that could potentially hinder safety such as instructions for use, allergen statements, dosages, warning statements and more.

If documents or digital packaging assets do not contain live text, the absence of OCR technology would force content revision tasks to be done manually. With files or labels that include small text, graphics of text, and multilingual files in different languages and scripts, this could prove to be a time-consuming and almost impossible task.

By automating the extraction of rasterized text, OCR not only accelerates the proofreading process it also provides a level of accuracy for document and label inspections that was not previously possible, as it allows for a character-for-character precision level

Thanks to this technology, pharmaceuticals, medical device, and CPG companies can ensure that their customers remain safe thanks to the mitigation of potential errors slipping by.

Accelerated Scaling of Global Operations

Scaling globally often comes with the challenge of dealing with multiple languages, different scripts and the obligation of adhering to global regulatory standards—noting that the complexity is compounded when those tasked with proofreading are not native to the languages they are faced with.

Verify’s OCR feature facilitates the extraction of text for translation purposes which supports the localization of documents. This reduces the risk of errors in translated content, whether it be regulatory, promotional documents, or labels.

This allows brands to scale globally at a quicker rate by efficiently and safely distributing error-free products and content across their target markets.

With Verify’s new AI-powered OCR feature, the software has the ability to proofread and validate content in various languages and scripts even if they are in a flattened format, enhancing efficiency and promoting consistency in communication, facilitating smoother global expansion strategies.

Faster Product Time-to-Market

For regulated industries, being first to market offers a huge competitive advantage with often limited market share to capture before it’s too late. Thankfully, Verify’s new OCR feature leverages AI technology to expedite the proofreading process, reducing the overall time it takes to bring products to market.

For teams who deal with proofreading regulatory submissions, batch records, promotional and marketing materials, as well as labels or packaging assets, optical character recognition will prove to be particularly beneficial.

By automating text extractions and reducing the need for manual content revisions and manual data entries, content revisions are now sped up throughout the product development lifecycle, allowing companies to respond more swiftly to market demands and gain a competitive edge.

This feature will also specifically benefit label labeling teams as the content they review includes both physical label scans as well as e-labels. In these cases, labeling teams are often forced to manually review and proofread within strict deadlines—increasing the risk of errors, and often delaying product time to market for sometimes life-saving drugs and medical devices.

With Verify’s new OCR feature, these teams will not only accelerate their speed to market, they will also have complete confidence that their documents and labels are accurate when they hit the market.

Protect Your Brand’s Reputation

Verify’s OCR feature acts as a safeguard against damaging content errors, which can lead to catastrophic consequences on a brand’s image.

By maintaining the integrity and accuracy of content, the software protects brand reputation and instills confidence among customers, stakeholders, and the wider public. It reduces the risk of typographical errors that could impact brand perception and contributes to a cohesive and reputable brand image.

OCR allows regulatory, commercial, labeling professionals in regulated industries, and agencies to achieve streamlined workflows, and elevated brand excellence. With this feature, they can deliver accurate, compliant, and impactful content and packaging assets to market, contributing to the overall consistency and success of their brand.

Begin Your AI Journey with New AI-Powered OCR!

The official launch of Verify’s AI-Powered OCR feature signifies a transformative moment for proofreading in regulated industries.

This feature brings innovation to the technology gap that was previously stunted by manual processes, providing a solution that significantly reduces the risk of errors and ensures compliance in industries that need to adhere to strict regulations.

Verify’s new OCR launch also goes beyond the needs of regulated industries and actively contributes to increased patient and consumer safety assurance, accelerated global operations, faster time-to-market, and the protection of brand reputation.

This innovative feature leverages the latest AI technology to reinforce Verify as a market-leading proofreading solution for regulated industries, empowering professionals with cutting-edge solutions and setting a new standard for excellence in compliance and proofreading workflows.

If you want to experience these benefits and more, begin your AI journey and try Verify’s OCR feature for free today.

If you want to discover the full capabilities of our innovative cloud-based proofreading software, book a demo of Verify and see firsthand the transformative impact it will have on your proofreading and quality control processes.

Why Regulatory Affairs Teams Need Document Comparison Software in 2024

Date: February, 2024 | Category: Proofreading | Author: Hana Trokic

Why do regulatory affairs teams need document comparison software in 2024?

For Regulatory Affairs, where adherence to strict compliance standards and efficient quality control processes are critical, the use of technology to help ease daily workflows has become particularly apparent in the past decade—2024 is expected to be no different.

While Regulatory Affairs teams are faced with growing complexities due to large content workflows, ever-changing regulations, and faster-than-ever product-to-market times, they continuously turn to technology to address bottlenecks in their proofreading and compliance review processes.

One tool that has been proven vital for the content reviews of Regulatory Affairs professionals is document comparison software which helps proofread critical content at scale, mitigate risks of financial losses, and expedite product time to market.

What is Document Comparison Software

Document comparison software allows users to compare two and identify their differences within seconds.

The software is designed to help users detect changes made to files as they move through revision and submission cycles, correcting errors, ensuring consistency, and overall simplifying proofreading processes while increasing accuracy and efficiency.

Document comparison software inspects digital files, including labels and packaging materials, to find any discrepancies between the two. A simple inspection will reveal and pinpoint differences allowing adjustments and corrections to be made in record time.

This technology plays a crucial role in regulated industries such as pharmaceuticals, and consumer packaged goods where precise and accurate documentation is essential from reviewing initial drafts to final submission documentation.

Automated Quality Control

Document comparison software simultaneously serves as an automated quality control tool that expedites the proofreading process and enhances the accuracy of your work.

This type of software automates the revision process through digital inspections that can detect errors across files and documents at all stages of the content lifecycle – even in the early stages. By catching errors early on, it helps to avoid the need for multiple inspections, saving time and resources for Regulatory Affairs teams.

Additionally, the software also contributes to the overall efficiency and saves resources for cross-functional teams. The streamlined process ensures that all teams involved can allocate their time and resources more effectively, creating a more coordinated and time-efficient work environment.

With document comparison software you can find discrepancies in text, spelling, images, graphics, barcode, color, and braille, making it ideal for Regulatory Affairs teams that deal with documentation that needs to adhere to strict regulations in all of these areas.

It also allows for the automatic inspections of digital files commonly reviewed by regulatory teams. This includes regulatory submissions, instructions for use, drug development documents, legal agreements, and much more.

With document comparison software, you can increase your confidence in regulatory submissions and subsequent product launches by ensuring that all documentation, labeling, and packaging go out to market without any errors.

Why is Document Comparison Software Important for Regulatory Affairs Teams in 2024

Document comparison software plays a critical role in Regulatory Affairs for several reasons, addressing this field’s unique challenges and requirements.

The software allows teams to increase the efficiency of their workflows by speeding up compliance review and proofreading processes, identifying errors, and ensuring the overall integrity and quality of their regulated documents.

The main reasons why document comparison software is important for Regulatory Affairs include:

How to Implement Document Comparison Software

Yes, regulatory affairs teams need document comparison software in 2024, but how easy it is to implement?

The ability to efficiently review critical documentation in Regulatory Affairs is essential for maintaining the accuracy of documentation and compliance. That is why document comparison software has become a valuable tool for organizations looking to enhance their document management processes in 2024 and beyond.

Here are simple steps you can follow to implement this innovative technology into your content revision workflows in 2024:

Automated Proofreading – A Leading Technological Solution

GlobalVision is the market-leading document comparison software and automated proofreading tool for Regulated Industries, specifically built with their requirements in mind.

For over three decades, this technology has proven to be beneficial for Regulatory Affairs teams. This successful track record with some of the world’s largest companies in the regulated industry is only expected to grow in the future, making 2024 the perfect year to start incorporating this transformative technology into your content revision workflows.

Any regulatory affairs team that deals with extremely sensitive documentation and products where even a minor content error can have detrimental or irreversible consequences can benefit from document comparison software.

The software’s diverse capabilities enable regulatory affairs teams to effortlessly maintain compliance of documentation across the asset lifecycle. Holistic inspections of documents enable the software to detect all errors, allowing for teams to make appropriate adjustments, ensuring the accuracy and quality of documents and critical assets.

This provides companies with an added layer of insurance and a sense of confidence, knowing that all errors are being identified, and amended and that only high-quality products are going out to market.

Conclusion – Why Regulatory Affairs Teams Need Document Comparison Software in 2024?

Regulatory Affairs need to make the best of technology available to them to ensure that they implement and use best practices in their workflows. This way, they will be able to optimize processes and stay profitable while thriving in the very competitive and fast-paced globalized markets in 2024.

As Regulatory Affairs teams continue to learn how to navigate the difficulties of ever-changing compliance regulations and look for ways to ease their proofreading processes, the adoption of document comparison software stands out as the ideal technological solution of the year.

If you’re ready to take the first steps towards error-free content in 2024, get started with GlobalVision’s document comparison software and begin experiencing the advantages of our cutting-edge technology today while seeing firsthand why regulatory affairs teams need document comparison software in 2024!

Proofreading Has Never Been Easier – Verify’s Winter Release Brings a New Approval Workflow for Custom Dictionary Words and More

Date: January, 2024 | Category: Company | Author: Hana Trokic

Introducing our Verify Winter Release.

Our latest version streamlines the addition of new terms with a new approval workflow for Custom Dictionary words, accelerating your content review process while reducing unwanted spell check errors.

This exciting release also brings new features and improvements tailored to diverse sectors including pharma, CPG, print and packaging, marketing agencies, and more—promising to improve content compliance while optimizing your workflow.

Enjoy the following upgraded features of our Winter Release:

With the addition of these cutting-edge features, Verify’s Winter Release not only sets new benchmarks for precision, efficiency, and compliance but also pioneers innovative capabilities, opening new possibilities in automated proofreading for regulated industries.

If you want to learn more about how to leverage our new features, book a Verify demo and begin experiencing these innovations in proofreading technology.

Add New Words to Custom Dictionaries With Increased Ease

Verify’s Winter Release also introduces a new built-in Approval Workflow for Custom Dictionary Words.

Pharmaceuticals, CPGs, and marketing agencies deal with content that includes many customs terms that are not readily available in regular dictionaries. These words include drug and brand names, or certain ingredient names and terms that are not standardized. In order for these words to not be flagged as errors during inspections, Verify allows for the addition of terms into custom dictionaries to further streamline inspection processes.

Our new approval workflow for Custom Dictionary Words allows users to seamlessly request approval from administrators to add words to custom dictionaries, ultimately streamlining day-to-day spell check and proofreading operations.

Watch our video to see the Admin Custom Dictionaries feature in action

Watch our video to see the User Custom Dictionaries feature in action

OCR: Save Time and Reduce the Risk of Non-Compliance

Verify continues to offer the most cutting-edge technology in cloud-based proofreading software by refining and optimizing our Optical Character Recognition capabilities. This feature allows users to inspect flattened text on documents such as labels, promotional material screenshots and supplier proofs by converting the digital images into readable, live text format.

Verify’s OCR feature leverages powerful artificial intelligence technology that detects characters within images or flattened documents, rendering a precise character-for-character text inspection possible.

This feature helps you save time on inspections and reduce the risk of non-compliance errors falling through. By automating the process of recognizing and extracting text from images or scanned documents, users can expect to drastically decrease the need for manual inspections, as well as the overall time needed to digitally inspect files.

By reducing manual processes, OCR also decreases the risk of human errors, safeguarding sensitive and critical documentation from errors that can lead to financial losses and the potential of a negative brand image.

While OCR is intended for all users, it will prove to be particularly beneficial for content, creative, regulatory, and labeling specialists in a variety of sectors from pharmaceuticals, print and packaging, prepress, and marketing agencies.

Watch our video to see the OCR feature in action

Revamped Prep Stage and Filtering Tool in the Results Stage

You can now expect to go through inspection results in record time through the new Prep Stage options and Filtering Tool in the Results Stage. Previously, users did not have the option to opt out of Text Inspection, and when reviewing inspection results, users sometimes had to go through large amounts of results cards with no clear and efficient method to filter and resolve them.

Now, users can select exactly which types of inspections they want to perform from the Prep Stage, and all Results get automatically segmented into 5 separate panels with their own unique default filters: Text, Spell, Graphics, Barcode, and Braille. You will also still have the option to view all results together with the “All” filter function.

This will allow you to view results in a more clear and concise manner and tackle differences by priority and importance, ultimately improving the revision process and allowing you to make corrections and improvements with greater ease.

See the new revamped Prep Stage and Filtering Tool below

Enhanced Graphics Inspection Capabilities

For those who heavily focus on graphics inspections, the Verify Winter Release also offers game-changing features to ensure the accuracy of your graphics.

Ability to Manage Spot Colors in the Prep Stage

This release also brings the ability to manage Spot Colors in the Prep Stage (also known as “Separations Control), expanding graphics inspection capabilities by ensuring a more comprehensive assessment of files, resulting in the heightened accuracy to your graphics files.

In the Prep Stage, a new option called ‘Spot Color Controls’ will now allow you to turn Spot Colors on or off to ease your revision process and allow you to view results and make needed adjustments efficiently.

Regulated industries such as pharmaceuticals, print and packaging, CPG, as well as agencies deal with complex workflows and often have limited power over the composition (layers and spot colors) of the files that need to be inspected. If the presence of a Spot Colors is hindering a successful graphics inspection from happening, the inability to turn that Spot Color off may reduce the accuracy of any given inspection, or make the inspection impossible. With the addition of this new feature, this bottleneck will be eliminated allowing for more seamless inspections.

Watch our video to see the Spot Colors Control feature in action

Graphics Inspection Captures Live Text Differences in Red Boxes

When running a graphics inspection, Verify will perform a pixel-for-pixel overlay, detecting all deviations, including deviations in live text, and will now capture them all within a red box.

By grouping and visualizing all differences found, this feature ultimately reduces confusion about which elements are being inspected when enabling Full Page Graphics.

See the new Graphics Inspection Improvements below

Scale Globally With Improved Accuracy of Asian and Right-to-Left Language Text Inspection

Multinational brands and agencies need to adhere to the compliance requirements of global authorities of the countries where their products and content are distributed, and are often faced with inspecting languages such as Asian text and right-to-left texts, such as Arabic and Hebrew, on various types of documents.

Without adequate processes and solutions, these companies are forced to either outsource these tasks or perform the inspections manually. This can lead to slow revision processes, delayed product-to-market times, and can ultimately hinder a company’s ability to scale its brand globally.

We improved our text inspection algorithm that recognizes and compares Asian characters and Right-to-Left languages. This allows multinationals to render more accurate inspection results and consequently, improve the quality of their multilingual documentation and packaging assets.

Reduce Unwanted Spelling Results

The Winter Release also brings new improvements to the spelling inspection algorithm and now offers a more reliable dictionary, rendering more accurate results for the following:

This is particularly beneficial for global brands and agencies that need to ensure all of their distributed content is accurate and free from all errors. Much like with multilingual documentation, without proper processes and software to help with these quality control tasks, international brands and companies may need to outsource tasks or do inspections manually. This can slow down revision times, delay product launches, and hinder global brand expansion.

Verify addresses these problems and offers a comprehensive and seamless solution to all organizations in a wide range of markets who want to ensure the quality of their products and brand.

See the new Reduced Unwanted Spelling Results feature below

Verify for Improved Proofreading

Verify’s Winter Release marks a significant advancement for cloud-based automated proofreading. Not only does it set new standards for precision, efficiency, and compliance, but also the refinement of OCR capabilities, streamlined custom dictionary workflows, revamped filtering tools, and enhanced graphics inspection features demonstrates GlobalVision’s commitment to delivering a seamless and accurate proofreading experience.

These innovations will elevate the quality of document inspections but also address specific challenges faced by diverse sectors, from regulated industries such as pharmaceuticals and print and packaging to creative sectors such as marketing agencies.

With a focus on reducing manual processes, improving inspection accuracy, and catering to the process complexities of global corporations, Verify empowers users to enhance the quality of their critical documentation. Our Winter Release not only meets but exceeds the evolving needs of regulated industries, making automated proofreading more accessible, efficient, and reliable.

To explore and leverage these cutting-edge features, book a demo of Verify and see firsthand the transformative impact it will have on your proofreading and quality control processes.

Customer Spotlight: IPG Health Leverages New Verify Features to Further Improve Proofreading Efficiency

IPG Health, a renowned network of agencies focused on health communication and marketing, serves top global pharmaceutical, biotech, and life sciences companies.

More specifically, the new approval workflow for custom dictionaries — based in part on significant feedback from the IPG Health Editorial team — streamlines their spell check operations, and the newly added filtering options and improved graphics inspection accelerate their proofreading reviews while helping to ensure accuracy.

IPG Health is one among the many global organizations and life sciences companies leveraging Verify’s latest innovations!

Medicine Packaging: Navigating Regulations in the UK

Date: January, 2024 | Category: Compliance | Author: Hana Trokic

In the UK healthcare industry, medicine packaging plays a crucial role in ensuring the efficacy and security of not only medical products but of consumers as well.

Over the years, requirements of UK medicine packaging have undergone significant changes, driven by advancements in technology, changes in consumer expectations and needs, and, most importantly, the ever-evolving stringent regulations imposed by regulatory agencies such as the MHRA.

Understanding and navigating these regulations is essential for medical companies to bring their products to market quickly and securely, and for healthcare professionals to ensure patient safety when prescribing medicine.

The Early Days of UK Medicine Packaging

Throughout history, the main role of UK medicine packaging has been to safeguard and conserve the contents of medical products. Glass bottles and vials were commonly used and were typically sealed with cork stoppers.

These bottles were usually accompanied by simple labels containing essential information. The labels were essentially handwritten instructions and information on paper that would be wrapped around the bottle. Overall, packaging was basic, serving the primary purpose of protecting the medication from external contaminants.

However, as the medical industry advanced, so did the need for standardized and regulated packaging to ensure patient safety and facilitate the administration of medications.

Blister Packs and Pill Bottles

As medicine research advanced, so did the need for more sophisticated packaging. In the mid-20th century, blister packs, the ones we so often see today, emerged as a popular choice. This sealed, foil-based packaging, offered enhanced protection against moisture and air and helped in extending the shelf life of medications.

Glass bottles were becoming less common as plastic pill bottles became a more popular substitute. They provided a more user-friendly and portable alternative to the old, heavy, and fragile glass bottle.

The Rise of Regulation in UK Medicine Packaging

While advancements in UK medicine packaging were present throughout the 20th century, the greatest turning point came with the strict implementation of medicine regulations aimed at standardizing the industry. This was due to the fact that traditional UK medicine packaging and the lack of proper guidance and regulation were proving to be greatly limited in ensuring the safety of products and consumers.

Regulatory agencies have been present globally since the beginning of the 20th century, but in the UK, the Medicines and Healthcare products Regulatory Agency (MHRA) has been at the forefront of setting guidelines to ensure the quality, safety, and efficacy of medical products since 2003.

Their main responsibilities include:

Since its implementation, the United Kingdom has played a pivotal role in shaping the evolution of UK medicine packaging through its stringent regulatory framework. The MHRA consistently sets forth updated guidelines that govern the packaging of medicine, ensuring safety, efficacy, and adherence to quality standards.

Labeling Requirements of UK Medicine Packaging

UK medicine packaging is made up of many different components that are all strictly regulated and controlled to ensure its accuracy and safety for use and consumption.

One of the most critical aspects of UK medicine packaging is the labeling, or the information provided on labels. Regulations mandate that packaging must include essential details such as the name of the medicine, dosage instructions, expiry date, batch number, and manufacturer information, to name a few.

Additionally, UK medicine packaging labels often feature critical safety information, such as potential side effects and storage guidelines. The main goal of a label is to ensure that individuals administering or consuming the medication are well-informed about its proper use and potential risks.

Compliance with labeling regulations not only supports the safe and effective use of medicines but also plays a pivotal role in promoting transparency and accountability within the medical industry. Strict adherence to labeling requirements contributes to the overall goal of ensuring public health by providing users with all the necessary information and knowledge needed to make informed decisions about their healthcare.

Tamper-Evident Measures

Tamper-evident packaging is described as “having one or more indicators or barriers to entry which, if breached or missing, can reasonably be expected to provide visible evidence to consumers that tampering has occurred.”

These measures in UK medicine packaging play a crucial role in ensuring the safety and integrity of medical products. The measures are implemented to provide visible signs of interference, making it evident if a package has been tampered with or compromised.

Common tamper-evident features include seals or bands that are broken or altered when the packaging has been opened. By incorporating these features and measures, UK medicine packaging manufacturers aim to protect consumers from potential tampering, contamination, or unauthorized access to medications.

Tamper-evident packaging not only serves as an added layer of protection and security but it also builds trust among patients and healthcare professionals, assuring them of the authenticity and safety of the medicine inside a package. This added security measure contributes significantly to maintaining the quality and reliability of medicine products throughout the supply chain, ultimately safeguarding public health.

Child-Resistant Packaging

Another important addition to UK medicine packaging regulations came in the later half of the 20th century. Child-resistant packaging became a requirement, addressing concerns about accidental ingestions and poisoning of young children. This type of packaging is designed to be difficult for children under the age of five to open, thus reducing the likelihood of unintentional ingestion.

Child-resistant UK medicine packaging was first introduced into the United Kingdom in the mid 1970s but only became standardized in 2001. Since then, a number of different regulations have been put in place, including European and International standards, as well as the Human Medicines Regulations 2012 and GHS/CLP, which became fully effective in 2015.

Since its introduction, child-resistant packaging has undergone many changes, not only in increasing resistance to potentially being opened by children but also in optimizing usability for adults. There have been continuous efforts to increase the safety of these products and their packaging with constant new developments in packaging improvements.

Barcoding and Serialization

Barcoding and serialization are integral components of modern UK medicine packaging, designed to enhance traceability, authenticity, and overall supply chain security.

Barcoding involves the assignment of unique identifiers, typically in the form of barcodes, to individual medicine packages. This unique identification enables efficient inventory management, reduces errors in product distribution, and facilitates rapid tracking throughout the supply chain.

Serialization takes this a step further by assigning a distinct serial number to each medicine unit, allowing for precise tracing of products from manufacturing to distribution to the end-user. These measures not only contribute to streamlined logistics but also play a pivotal role in combating counterfeit medicine and in ensuring patient safety.

GMP (Good Manufacturing Practices)

Good Manufacturing Practices (GMP) in UK medicine packaging represent a set of strict quality standards and guidelines that medicine manufacturers must adhere to in the production of packaging materials and systems.

GMP regulations ensure that the entire product lifecycle, from development and production to labeling and storage, follows specific protocols aimed at consistently delivering safe and high-quality UK medicine packaging.

Compliance with GMP standards is crucial for maintaining the integrity of medicines and preventing contamination or defects in the packaging. These practices encompass various aspects, including personnel training, hygiene, documentation, and equipment calibration.

By adhering to GMP in UK medicine packaging, manufacturers uphold the highest standards of quality assurance, contributing to the safety and efficacy of medical products and reinforcing the trust of healthcare professionals and consumers in the integrity of the overall medicine supply chain.

Environmental Sustainability

In recent years, there has been a growing emphasis on environmental sustainability in UK medicine packaging. Regulatory agencies are encouraging medical companies to adopt eco-friendly packaging solutions, reducing the environmental impact of the industry.

Manufacturers increasingly focus on adopting eco-friendly practices and materials to minimize their carbon footprint. This includes exploring recyclable, biodegradable, or compostable packaging options and optimizing packaging designs to reduce material usage.

Additionally, efforts are being made to enhance energy efficiency in the production processes and choose environmentally responsible printing inks and coatings. The aim is to strike a balance between ensuring the safety and efficacy of medical products while minimizing the environmental impact associated with their packaging.

By embracing sustainable practices, the medical industry not only aligns itself with global environmental goals but also responds to the growing demand from environmentally conscious consumers.

Smart Packaging and Technological Integration

UK medicine packaging in the 21st century vastly differs from the packaging used over a hundred years ago. In recent years, technological advancements have revolutionized UK medicine packaging, with smart packaging becoming the newest trend in the industry.

Smart packaging refers to the emerging technologies within the packaging industry that increase consumer and business utility alike, all while simultaneously increasing the simplicity of accessing and tracking the information surrounding products and companies.

This packaging is equipped with features like temperature monitoring, NFC (Near Field Communication) tags, QR codes, and interactive labels. These innovations not only ensure the integrity of the medication but also empower patients with information and enhance overall healthcare management.

Innovation in UK Medicine Packaging – Automated Proofreading

As the accuracy of all packaging content is of extreme importance, technological solutions that ensure packaging integrity are also increasing in popularity. Automated proofreading is one of those innovative solutions in UK medicine packaging.

Automated proofreading aids in maintaining packaging accuracy by inspecting all types of regulatory content that would be present on UK medicine packaging. It helps companies uphold packaging and manufacturing standards with greater ease and efficiency, ensuring compliance with UK medicine standards and beyond. This technological innovation provides better proofreading results and enables higher-quality UK medicine packaging as it acts as an added layer of security in quality assurance processes.

In essence, automated proofreading works by comparing two documents to find discrepancies between the two. The innovative software conducts comprehensive inspections and proofreads all packaging assets from text, color, graphics, barcodes, braille, and more.

Through automated proofreading, inspections of packaging components are completed exponentially faster than traditional proofreading, and a task that once took hours or days to complete is now reduced to only a few minutes.

Benefits of Automated Proofreading

Automated proofreading plays a crucial role in enhancing the quality and compliance of UK medicine packaging. Some ways in which automated proofreading helps in UK medicine packaging includes:

By leveraging automated proofreading in medicine packaging, companies in the industry can improve the overall accuracy, quality, and compliance of their packaging. This not only increases patient safety but also helps maintain the integrity of medical products.

Customer Case Study: Automated Proofreading For Error-Free Medicine Packaging

Prior to implementing GlobalVision, all materials at Bristol-Myers Squibb (BMS) Shanghai were manually reviewed by their Quality Control department. Manually proofreading each packaging component often took too long and was too reliant on the SASS Project Manager. As they only relied on the human eye to catch errors, the risk of faulty inspections was high.

For a major pharmaceutical company such as BMS, letting a critical packaging error slip by could have damaging effects on its reputation. It may also result in reprints or recalls which can impose huge costs on the business. Worse, it can cause potential consumer harm if these packaging errors made it to market.

The BMS Quality Control Department uses GlobalVision to inspect incoming packaging materials such as cartons. Batch by batch, the packaging is compared to the approved samples to catch any differences between the two. As a result of the automation, the Quality Control Department has found that its revisions could be completed faster and more effectively.

Through the implementation of GlobalVision, BMS Shanghai increased its level of efficiency and accuracy, further aligning its commitment to quality when it comes to both packaging and patients.

The Future of UK Medicine Packaging

The transformation of UK medicine packaging throughout the years has been shaped by dynamic factors such as evolving regulations, changing consumer needs, technological advancements, and a heightened emphasis on safety and responsibility.

The industry, from basic glass bottles to cutting-edge smart packaging, has consistently adapted to meet contemporary demands, with the MHRA playing a pivotal role in maintaining and enhancing these standards.

Each advancement in the industry shows a commitment to ensuring the highest quality and safety standards. Notably, the integration of technological solutions, including automated proofreading tools, emphasizes this commitment by improving accuracy and safeguarding packaging and, by default, healthcare professionals and consumers alike.

Automated proofreading serves as a comprehensive solution that not only streamlines quality assurance processes but also facilitates accuracy and compliance for UK medicine packaging manufacturers and beyond.

To experience the transformative power of automated proofreading, request a demo of our innovative software and witness firsthand how this technology can revolutionize your daily business practices.

Revolutionizing Braille Inspection: Introducing the Upgraded GVD Braille Module

Date: December, 2023 | Category: Compliance | Author: Hana Trokic

In regulated industries, where adherence to standards and accessibility is crucial, Braille is a vital component of any product’s packaging or labeling to foster compliance and inclusivity.

Braille, a universally accepted system of writing designed for individuals with visual impairments, is critical in ensuring that information, particularly in industries subject to strict regulations such as pharmaceuticals, is universally accessible.

This code not only empowers individuals with visual disabilities by providing them with independent access to written content, but it also aligns with non-discrimination principles mandated by regulatory agencies.

From a quality control perspective, Braille Inspection and accuracy play an important role as Braille is mandatory on pharmaceutical packaging all across Europe, and is strongly recommended by the FDA in Western markets, while other regions such as the ASEAN markets are working to heighten inclusivity by implementing braille requirements on packaging soon.

For regulatory industries to ensure the complete accuracy of their products, they need to ensure comprehensive revisions and inspections of their content. This includes text, graphics, barcodes, colors, and of course, braille for an all-encompassing quality control process. One way to ensure this accuracy is through modern-day technological solutions and innovations that ease these critical yet demanding revision tasks.

The New GVD Braille Module

One such innovation that stands out for compliance reviews is the newest upgrade from GlobalVision—the GVD Braille Module. This new braille inspection technology sets a new standard for fast, accurate, and comprehensive braille inspections.

The GVD Braille Module allows regulated industries such as pharmaceuticals and print and packaging to automate braille height inspections with unparalleled granularity and speed, providing braille compliance data for each individual braille dot. This market-disrupting product brings unprecedented braille height detail, as well as meticulous braille translations to ensure complete accuracy and compliance with industry regulations across all printed assets.

This advanced technology is not just an upgrade in compliance inspections, it’s a breakthrough in braille inspection.

Here’s what to look forward to with the newest GVD Braille Module:

Unmatched Braille Inspection Speed and Precision

With 10X faster braille height inspections and the support of full-size press sheets, GlobalVision’s newest automation technology surpasses the traditional DotScan software and all other competitors on the market. Printing & packaging and pharmaceutical companies can now expect to automate braille inspections with granularity and speed that was previously not possible.

The technology not only accelerates the inspection process but also ensures unparalleled precision, reducing the risk of oversights. Beyond heightened efficiency, the increased automation of the entire compliance inspection process allows organizations to redirect resources to more strategic tasks, fostering innovation and growth internally.

GlobalVision’s braille inspection technology redefines industry standards by combining speed and granularity, transforming compliance inspections into a faster, more comprehensive and accurate process.

Save Resources and Eliminate Unnecessary Overhead

With this new release, all braille inspection features are embedded within the robust GVD platform. This allows companies in regulatory industries to save money and resources by eliminating the need and overhead of managing multiple systems.

The GVD Braille Module consolidates all packaging quality control processes as it is fully embedded within the robust GVD system, allowing for text, graphics, barcode inspections and more, rendering the use of a separate system obsolete.

This upgrade ensures that every aspect of your quality control process can be seamlessly executed within a single platform. The efficiency gains are unmatched, as companies can now navigate the entire process, including the previously tedious braille inspection, with speed and precision, while simplifying their workflows and enhancing overall productivity.

This innovation not only streamlines operations but also positions the GVD Braille Module as an industry leader, offering unparalleled ease and efficiency to the market.

Ensure Adherence to Compliance Regulations

For regulated companies, the need to adhere to strict guidelines and requirements is critical. GlobalVision’s latest advancement in braille inspection technology represents a crucial upgrade in addressing this concern by guaranteeing ongoing braille compliance with the Marburg Medium Font Standard as well as the ISO 17351:2013 requirements for braille labeling on medicinal products.

This upgrade not only ensures precision and accuracy in braille, but, more importantly, serves as a proactive measure to prevent potential regulatory sanctions. By aligning seamlessly with established standards, this technology provides regulatory companies with the assurance that their braille labeling processes are not only efficient but also in strict accordance with mandated guidelines, protecting against potential legal and regulatory penalties.

Global Scalability

The GVD Braille Module isn’t confined to a specific language or region. It scales globally, inspecting braille translations in an impressive 44 languages against a master file. This global scalability ensures that the technology is not only cutting-edge but also inclusive and diverse, catering to the many linguistic needs of multinational enterprises.

By accommodating such a wide linguistic range, the GVD Braille Module becomes a versatile tool that addresses the diverse needs of companies worldwide, acting as a positive lever toward their global expansion strategies.

Detailed Reports and Compliance Data

One of the standout features of the GVD Braille Module is its ability to provide you with highly detailed reports for each braille dot across all regions, ensuring that every single dot meets regulatory standards.

The GVD Braille Module allows you to achieve unprecedented granularity in braille inspections with in-depth reporting for each individual braille dot across all braille regions, including multi-panel regions. This means the software goes beyond basic inspection data and provides a level of inspection scrutiny unparalleled in today’s market.

The Future of Braille Inspection

In an era where technology and automation is the driving force behind progress, the GVD Braille Module stands out as a revolutionary solution in the field of braille inspection. This comprehensive solution surpasses all previous inspection systems and doesn’t just meet industry standards but sets a new benchmark for efficiency and accuracy.

As industries strive for greater innovation in technological solutions, the GVD Braille Module allows you to overcome all previous inspection limitations and embrace new technology that improves the entire quality control process.

GVD Braille Module is not just an upgrade, it’s a revolution in braille inspection. To try the new standard in braille inspection yourself, book a personalized braille demo and begin revolutionizing your compliance inspections today.

Manual vs. Automated Proofreading: A Comprehensive Guide

Date: December, 2023 | Category: Proofreading | Author: Hana Trokic

The way we communicate with others is essential. How we express ourselves through different outlets is crucial in getting our exact message across exactly how we intend it to.

The same can be said for businesses, as companies spend immense amounts of time, money, and resources ensuring they communicate their brand seamlessly to every consumer. Yet, a brand’s image isn’t just a mission statement or a slogan. Behind each brand is a mountain of content and documentation – from packaging and labeling to legal, digital and printed content.

It begs the question. Manual or automated proofreading? Which method will better ensure brand integrity when products go out to market?

What is Manual Proofreading?

Manual proofreading refers to the process of carefully reviewing and checking documents or content by human experts to ensure accuracy, compliance, and adherence to established standards and regulations. This process involves meticulous examination of the content for errors, inconsistencies, or any deviations from the regulatory requirements.

The Risks of Manual Proofreading

Manual proofreading implies human proofreading of all documentation before it goes out to print.

With an endless stream of documentation that needs to be constantly reviewed, manual proofreading is not without its challenges. Not only is it time-consuming, but the chance of human error is high, while some mistakes can result in significant consequences for companies, be it financial, legal, or brand-wise.

Other companies face the challenge of having documents that simply cannot be manually proofread since errors in barcodes, fine print, and graphics are often far too difficult for the human eye to detect.

While manual proofreading will always play an essential role in many quality assurance processes, it is important to note its many risks if used as a primary method of proofreading.

Some of the risks associated with manual proofreading include:

What’s more, manual proofreading is not highly accurate when dealing with graphics, color deviations, barcodes, or braille. Unless the mistakes are evident, the human eye cannot detect minor discrepancies that otherwise compromise the integrity of the overall design, packaging, label, and so on.

To stay competitive in today’s market, companies simply cannot afford the setbacks of manual proofreading. This is why many modern-day businesses turn to automated technologies to help increase the speed, accuracy, and efficiency of their revision workflows.

Want to learn more about the risky business of manual proofreading? Read our blog post here.

Automated Quality Control as a Proofreading Solution

Automated quality control and proofreading stands out as a perfect proofreading solution for businesses who wish to reduce the risks and setbacks that come from manual proofreading.

This technological innovation provides better proofreading results and enables complete and comprehensive inspections of critical content and documentation.

In essence, automated quality control and proofreading works by comparing two documents to find discrepancies between the two. The software conducts comprehensive inspections and proofreads everything from text, color, graphics, barcodes, braille, and more. Inspections are completed exponentially faster than manual proofreadings and a task that used to take hours or days is now reduced to only a few minutes.

The Benefits of Automated Proofreading

Automated quality control and proofreading offers several advantages across various industries and processes.

Some key benefits include:

To learn more about how automation can help your organization avoid costly mistakes, read Manual Proofreading Errors: How to Stop Label Recalls in Your Supply Chain

Automated Proofreading for Error-Free Content

One area where companies can largely benefit from automated quality control and proofreading is packaging and labeling. Pristine, error-free packaging and labeling not only increases customer loyalty to your brand, it’s also a necessity, regardless of industry.

It ensures that companies meet strict regulations from regulatory agencies such as the FDA for the United States, the MHRA for the United Kingdom, and EFSA for the European Union to name a few. This helps avoid potential compliance issues that lead to severe consequences.

Error-Free Packaging and Labeling

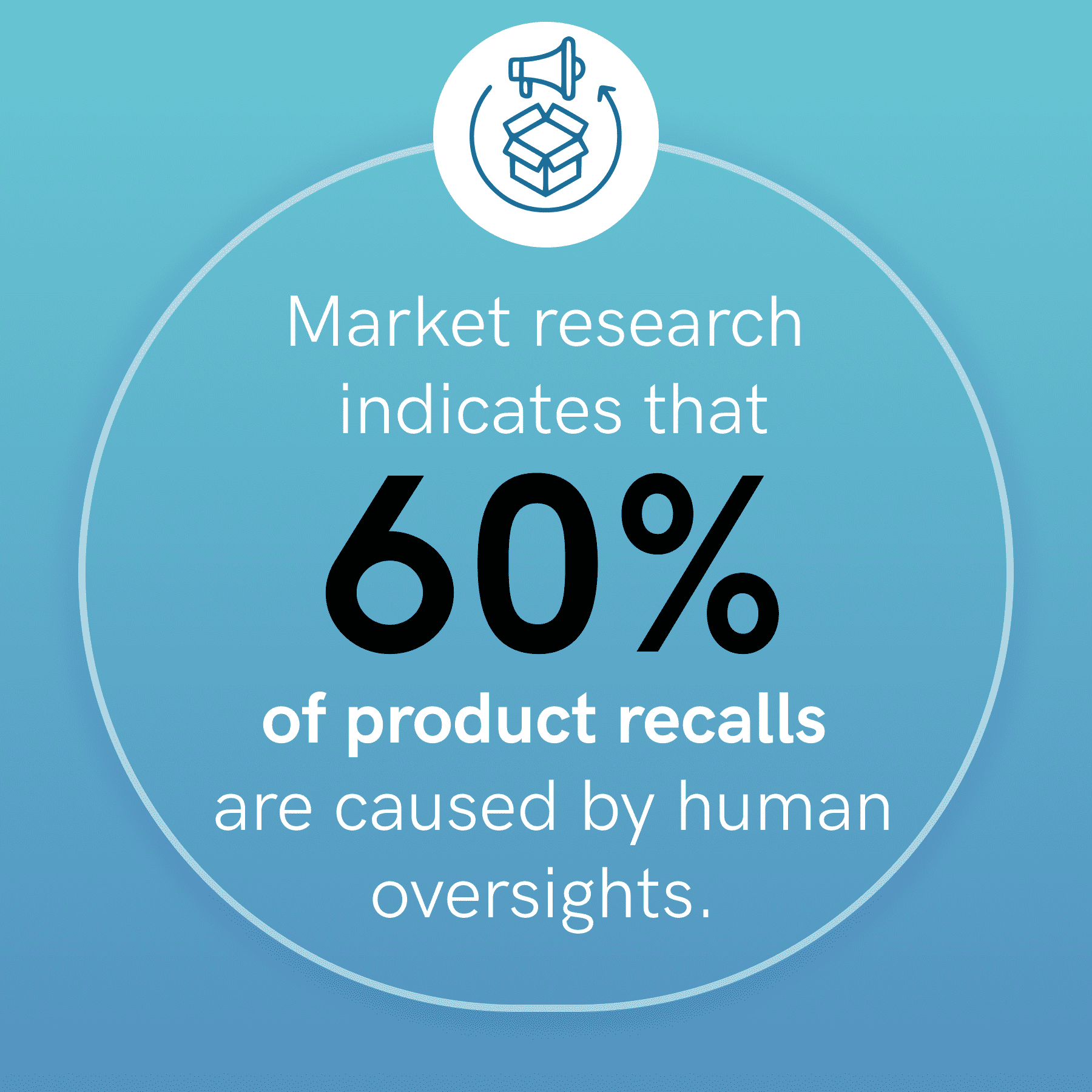

A packaging or label error doesn’t have to be fraudulent to be costly. In fact, a great deal of mistakes are simply caused by human error. Market research indicates that 60% of product recalls are caused by human oversights.

Human errors can easily be introduced and missed in content and only reinforce the need for added layers of reassurance, such as automated quality control and proofreading software.

Performing label and packaging inspections at each stage of the revision cycle reduces the risk of a recall and the number of required revision cycles, so products get to market faster, without any errors.

Consequences of Label Errors

Taking the food and beverage industry as an example, packaging must contain what the label entails. If the FDA has reason to believe packaging is inaccurate, that it falsely claims the contents of the product inside, imports can be detained without physical examination. The product effectively gets prevented from being distributed and ultimately sold.

If a manufacturer is found to be guilty of breaching FDA regulations and compliance, the FDA may issue a warning. In the event the manufacturer does not comply and correct the issue, the FDA takes additional legal action to ensure the product gets removed from the market, without it being permitted to return until the issue has been corrected. Criminal fines and even prosecution may result depending on the infraction.

In the case of the pharmaceutical industry, which is also under the purview of the FDA and whose customers depend on packaging for accurate dosage information, it’s easy to see why penalties need to be especially severe. A single misplaced period can have huge negative ramifications.

Find out more about creating error-free content by reading Why Error-Free Packaging and Labeling Is a Must

Tips for Creating Error-Free Content

There are many different components involved when creating content for regulated industries, which includes packaging and labeling. To help ensure that you create error-free content and reduce the risk of dealing with a product recall, it’s always helpful to implement some best practices.

Proofreading Starts With Up-to-Date PDFs

Throughout a proofreading cycle, a PDF can go through many revisions before getting approved. Files can also be stored across different network shares or even on an individual’s local computer. It’s key to ensure you know where to find the most up-to-date PDF. By doing so, businesses will avoid sending the wrong PDF to print.

Check Barcodes Early

It’s common for graphic artists to put placeholders for barcodes to show where the final barcodes will be positioned on a file. An FPO symbol will often be placed on top of a barcode which stands for “For Position Only.” This is often missed when the print runs, resulting in the correct barcode not appearing.

It’s recommended to check barcodes on proofs which can be done through automated quality control and proofreading for checking barcodes or printing out the proofs and using a handheld verifier.

Proofread Printer Proof Prior to Approval

It’s easy enough to give a quick glance over artwork files and tell the printer to go ahead with the job, but this is not enough to ensure no mistakes have slipped through.

Conducting a thorough proofreading of files to check for errors in spelling, color, barcodes, and other content on a proof is essential. One way to do this type of check is to do a line-by-line visual comparison.

Standardize Design Tools

Do you know what versions of Adobe Illustrator your suppliers are using? Chances are they are all using different versions, which equals different functionalities and feature sets.

Ensuring everyone is on the same version means everyone is viewing the same file and that you have repeatable results. This also ensures there won’t be any unintended changes due to differences in software.

Continuous Quality and Improvement

Continuous testing in software is the new approach when developing products. Most software products today will have some level of automated testing completed to check against expected results. This helps to continuously test code and ensure quality throughout the development process.

Read 6 Tips for Creating Error-Free Packaging for more information about how to create perfect content every time.

There’s no reason why this methodology can’t be applied to any business’s revision cycle, regardless of industry. Using tools to perform routine tasks like preflight and PDF comparison can enable automation on a continuous basis to catch errors in files early on before products go out to market.

By implementing these best practices, businesses will see an immediate reduction in errors and an overall improvement in quality.

Want to learn more about automated quality control. Read our guide An Introduction to Automated Quality Control

Automate Your Manual Processes

To keep up with modern trends and ever-growing consumer demands, manual proofreading is simply not an adequate solution to allow for proper functions within a company’s quality assurance workflow.

While traditionally manual proofreading was the only method used to revise critical documentation, modern-day technology and innovations have allowed for more intelligent, more efficient solutions to get the job done.

With endless benefits and countless advantages to your workflow, automated quality control and proofreading is the leading solution for companies who want to revolutionize their revision processes.

To ensure the complete integrity and accuracy of all files, request a demo of GlobalVision today, and learn about all the advantages it can bring to your company while modernizing your current practices.

———————————————————————————————————————————————————

Related Articles:

Dempsey Corporation Transforms the Label Review Process with GlobalVision

Date: November, 2023 | Category: Customers | Author: Hana Trokic

About Dempsey Corporation