Risks of Manual Verification as a Proofreading Method

Date: January, 2022 | Category: Proofreading | Author: Hana Trokic

Before a product reaches the hands of consumers, there are thousands of behind-the-scenes steps, procedures, and inspections that have to be completed to ensure that the final product is perfect.

All aspects of the product must be free from error, including the packaging, labeling, and copy. Not a single word, letter, punctuation, or line should be out of place. On the contrary, companies might find themselves in critical situations either legally, financially, or socially and risk losing their brand reputation.

Setting up proper workflows where proofreading takes priority is crucial in product development to avert crises, allowing companies to deal with product management instead of crisis management. Yet, the importance of error-free packaging and print may be one of the most overlooked yet essential factors in the product life cycle as many still rely on manual verification.

This is why effective proofreading methods must be placed to ensure the quality and accuracy of each product that is sent out to consumers.

The Risks of Manual Verification

They say with great risk comes great reward, but some things should not be tampered with. Proofreading is one of them and should remain a complete and utter safe zone. Processes that enable its impeccable implementation should be undergone to ensure every product that makes it to market is error-free.

Yet, how is a product proofread? Manual proofreading was once a norm that implies human verification before it goes out to print. We’ve all been there; we know how brain-draining the proofreading process can be. At a certain point, words just look like words, and we lose the ability to make sense of it, leading to hasty, minor errors with potentially significant consequences.

A solution might be to employ larger labour forces to verify content manually. However, this is a more costly solution, and the revision process would also take up far too much time. This would halt efficient workflow processes and increase overall production time, a considerable setback in today’s face-paced, consumer-driven environment.

To stay competitive in today’s market, companies simply cannot afford the setbacks of manual verification.

What’s more, manual verification is not highly accurate when dealing with graphics, colour deviations, barcodes, or braille. Unless the mistakes are evident, the human eye cannot detect minor discrepancies that otherwise compromise the integrity of the overall design, packaging, label, and so on.

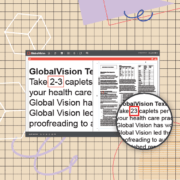

Automated proofreading software completes this task with utter ease and does so in a matter of seconds to minutes. Comparing the master document with the print, not only will it scan for all errors in text, colours, graphics, and more, it will pinpoint exactly where the deviations are located, allowing you to adjust accordingly in a fraction of the time.

The Disadvantages of Manual Verification

The disadvantages of manual verification are vast, and its setbacks far outweigh those that may occur while transitioning to automated quality verification. In fact, the practice of manual verification can potentially be more problematic than one might initially anticipate. Some common problems with manual verification include:

- High possibility of error

- Makes for less efficient workflow and production

- Time-consuming

- Requires greater resources

- Costly with regards to labour and revision time

- High risk, larger probability of defects and product recalls

Automated Quality Control as a Proofreading Solution

Automated proofreading technology stands out as being a vital component in today’s modern product development process.

This technological innovation provides better proofreading services and enables a complete scan and inspection of the entire verification process. Some might think implementing new software and technology can cause setbacks to company processes, but as technology continues to adapt and improve, these processes keep getting easier, faster, and more efficient.

Manual verification can’t even begin to compete with the vast capabilities of technological advances and innovations, much like automated quality control. Keeping up with market trends and demands, GlobalVision’s software solutions are specifically tailored to everyone using their services. Developed with the end-users in mind, difficulties using the software are scarce, and in no time, they will speed up processes and even make daily tasks easier and an integral part of workflows.

Simply put automated quality control works by comparing two documents, and finding the discrepancies between the two. The software almost entirely eliminates the need for manual proofreading and speeds up revision cycles to mere minutes. It eliminates the need of requiring manual labour to look over countless documents and content and simplifies processes to only a couple of easy-to-follow steps. What was once a multi-step process that would take a team several hours, days, or even weeks, has now become simplified by the work of one software program while revision teams have been drastically reduced.

Say Goodbye to Manual Verification

What was once the standard for proofreading processes has quickly been replaced by more advanced technology that makes these processes faster, easier, more accurate, and more efficient.

While some manual verification steps cannot be replaced, automated quality control brings unmatched benefits to the process that manual verification cannot compete with. As consumer needs continue to grow exponentially, businesses need to adapt to new challenges and move far away from traditional, outdated methods that have mostly become obsolete. With the introduction of new technologies, it has become a no-brainer to implement software that increases efficiency and accuracy in the workplace while decreasing unnecessary resources and costly mistakes.

Has your company modernized its practices and implemented innovative technologies to help speed production and business? Request a demo of GlobalVision today, and learn about all the advantages it can bring to your company while modernizing your current practices.

Related articles:

- What are the Benefits of Implementing a Quality Inspection System?

- 4 Reasons Why Your Business Needs a Graphics Inspection Tool

- Using Automation Technology to Manage Regulatory Compliance

- Solving The Content Efficiency Problem in the Pharma Industry

- Your Complete Guide to Meeting FDA Labeling Requirements

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated proofreading software. Sign up for our newsletter.