4 Reasons Why Your Business Needs a Graphics Inspection Tool

Date: December, 2020 | Category: Proofreading | Author: Kayla Caticchio

Not many aspects of design and production are still being done manually when it comes to packaging in 2020. Despite modern advancements, many businesses are still stuck in a rut of manual proofreading. The good news is that automation technology has been increasing in popularity over recent years, especially in the areas of quality control. Of these automation innovations, graphics inspection tools are becoming widely implemented across many industries.

Consider the importance of pristine packaging in today’s market. One of the most important aspects of a product’s packaging, graphics, help consumers distinguish between products and brands and allows important information to be communicated to the consumer.

A packaging’s artwork (or graphics) also contributes to protecting and maintaining a strong brand identity and must therefore remain consistent across all channels. Any errors in artwork can be harmful to the brand’s image, and in some regulated industries, they can even be harmful to the consumer.

This is where automated technology shines and prevents these errors from occurring. Continue reading to find out about the four reasons why your business needs a graphics inspection tool.

The Benefits of a Graphics Inspection Tool

There are significant benefits to implementing a graphics inspection system in your workflow for both the user and the company as a whole. From marketing and design to prepress and packaging teams, we’ve put together our top 4 reasons why it could be a game-changer in the area of quality control.

1. Automate proofreading for maximum efficiency

In most businesses that haven’t made the switch to automated quality control, graphics are inspected manually by members of the Quality Control department. This process is oftentimes long, tedious, and inefficient due to the amount of time it can take to visually inspect artwork files.

A graphics inspection tool would speed up the inspection process by conducting digital checks on artwork files at every stage of the workflow, reducing the workloads of individual proofreaders and proofreading teams.

According to GlobalVision users who have implemented graphics inspection tools, “[automation] has resulted in at least 50% time-saved proofreading” says one user. This maximized productivity would essentially multiply the workforce, eliminate inefficiencies, and give companies the ability to allocate more resources to bigger projects.

2. Reduce risk by catching critical errors early

Anyone who works with packaging knows just how detrimental an artwork error can be, especially in regulated industries like pharma and life sciences.

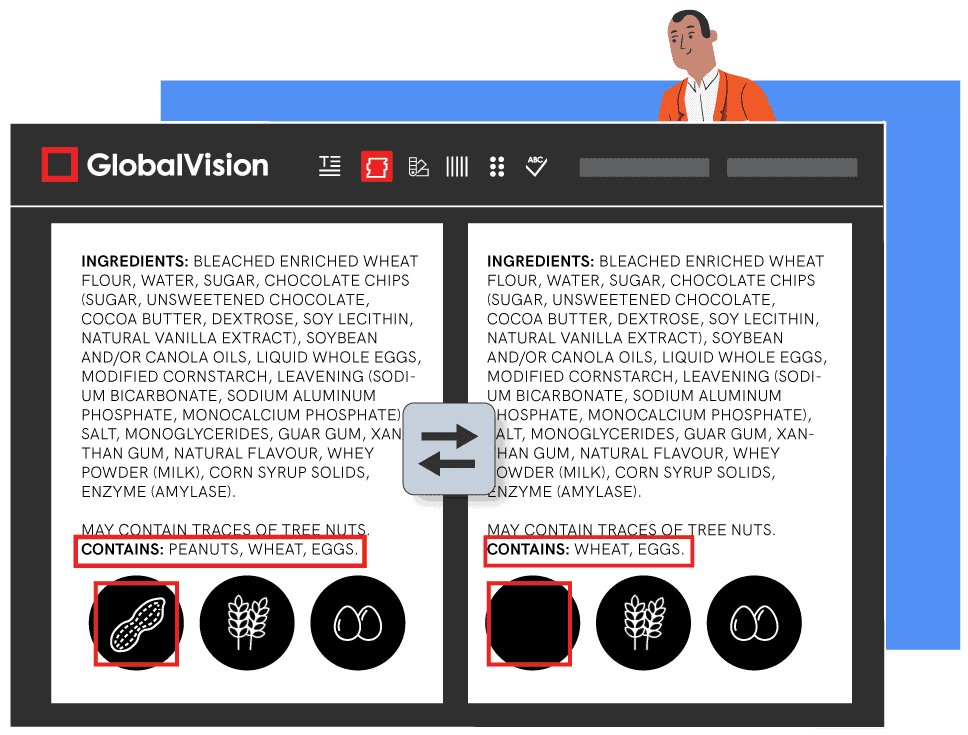

Despite proofreaders’ best efforts, it’s not uncommon for an error to slip by unnoticed. These errors can range from a missing artwork image to something more serious, like the wrong allergy information on a label. Either way, a missed error can cause significant damage to the brand.

A graphics inspection tool reduces liability risk by ensuring that all errors are caught early on, reducing the risk of reprints, customer complaints, and even recalls.

Starting at the artwork creation stage, an automation graphics inspection tool has the ability to pinpoint exact differences in artwork faster and more accurately than any proofreader would be able to do. For example, GlobalVision’s graphics inspection software allows the proofreader to run side-by-side comparisons of an artwork revision file and the approved version with pixel-to-pixel accuracy, ensuring there are absolutely no errors between the two.

This helps to maintain the integrity of packaging by keeping artwork consistent as files move throughout the quality workflow. “Graphics Inspection does a great job of picking up tiny differences in the documents I run through the program,” says a GlobalVision user in printing. “It saves me a lot of time picking up any differences I might have missed.”

3. Get products to market faster

Avoiding delays caused by long proofreading times is one of the main benefits of implementing graphics inspection software. What can normally take hours of manual proofreading time can be cut down significantly by going digital. With GlobalVision for example, hours of manual proofing can be cut down to 20 or 30 seconds per inspection, saving the user time and ensuring that projects are completed within time constraints.

From artwork creation to prepress stages, implementing a graphics inspection tool across your workflow eliminates any unnecessary delays between departments with fast and effective inspection results. For printers, in particular, catching artwork errors before files move to the printing stage helps avoid having to throw out entire batches of printed materials, saving both time and money for the company.

Users can also communicate results more quickly by sharing detailed inspection reports that include the results of all artwork checks, resulting in faster approval times, and therefore faster time-to-market.

4. Give your business a competitive edge

With increasing competition between brands, packaging needs to be absolutely perfect before it hits the shelves. Having a graphics inspection tool in place helps to differentiate yourself from competitors by showing customers that you care about quality control and are willing to invest to ensure that their products are of the highest quality.

For example, a consumer goods company would be more likely to work with a printer that uses automation at the prepress stage versus a printer that just relies on manual inspections that are prone to human error. “Customers who have seen the technology are impressed by automated quality control and the tool’s efficiency,” says one Graphics Inspection user. A graphics inspection software acts as an extra layer of security that gives your business an edge when it comes to technology.

Get started with Automated Graphics Inspections

Ultimately, deciding to implement a graphics inspection tool has many benefits for your business. From time savings to an increase in productivity levels, taking your quality control process into the modern age is a guaranteed way to help ensure continued growth for your business.

To learn more about the benefits of switching to automated quality control, request a demo of GlobalVision here.

_________________________________________________________________________________________

Related Articles:

What our customers think of our proofreading tools:

“Overall, the team is able to save between 10-15 minutes per label when proofreading with GlobalVision.”

– Imran Masood, Quality Specialist and Labs Head at Unilever – Dubai Personal Care Factory.

_________________________________________________________________________________________

Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

Keep up with the latest updates in automated quality control. Sign up for our newsletter.

Get your Complete Guide to Meeting FDA Labeling Requirements Here

Learn How Some of the World’s top Pharma Companies have Cracked the Efficiency Code with Automation