How Automation Technology Helps Protect Consumer Packaged Goods Brands From Critical Errors

Date: February 24, 2021 | Category: Proofreading | Author: Kayla Caticchio & Gabriella Naguib

- Increasing competition between brands creates the need for more rigorous quality control methods.

- Manual proofreading creates too much of a risk for letting a critical packaging error slip by.

- Consumer packaged goods companies are implementing automated quality control technology to detect any defects before products go to market.

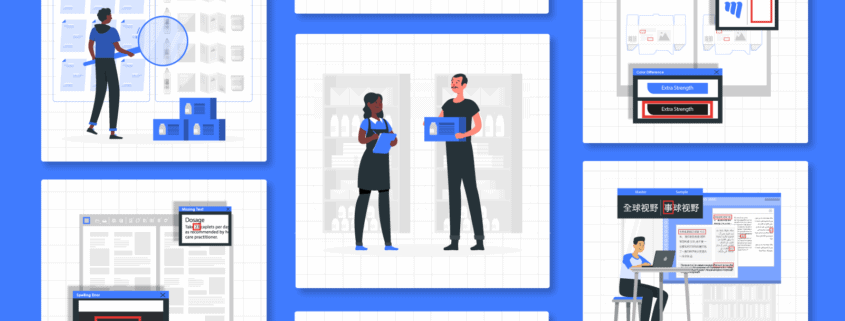

With consumer demands and preferences changing at a record pace, brands in the consumer packaged goods industry must be able to stand out in a highly competitive landscape. As they face challenges like expanding product lines, shorter turnaround times, and pressure from competitors, these companies must be able to effectively manage the product lifecycle from beginning to end.

One particular area to which CPG brands must pay close attention is quality control. In the consumer goods industry, the quality of labels and packaging is just as important as the quality of the product inside. These types of labels and packaging components contain product-specific information and suggest critical content that is carefully written and placed in order to protect the end users.

Whether dealing with food and beverages, cosmetics, or medications, regulatory and quality teams work around the clock to ensure that laws and regulations are being met to be able to sell their products in various markets. Depending on the product and market where it’s being sold, critical content requirements change considerably.

From ingredient lists and allergen warnings to dosages and expiration dates, the margin of error is extremely small when it comes to packaging or labeling errors. In the consumer goods industry, each brand has a social, environmental, and financial responsibility to ensure the complete accuracy of its product packaging at all times.

The Risks of Manual Proofreading

The use of automated quality control tools has increased in popularity over the years as consumer goods companies expand into new markets and in turn, must focus more of their efforts on ensuring error-free labels and packaging.

In an industry where consumers can make or break a brand, even the smallest of label mishaps can have detrimental effects on your company’s image and reputation. Wrong dosage or allergen information, for example, can lead to customer complaints and sometimes even recalls. In 2020, non-declared allergens and label errors were the leading cause of recalls in the food and beverage industry.

Aside from the financial burden associated with a massive recall, causing consumers to lose faith in your brand is perhaps the most costly mistake a company can make in today’s marketplace.

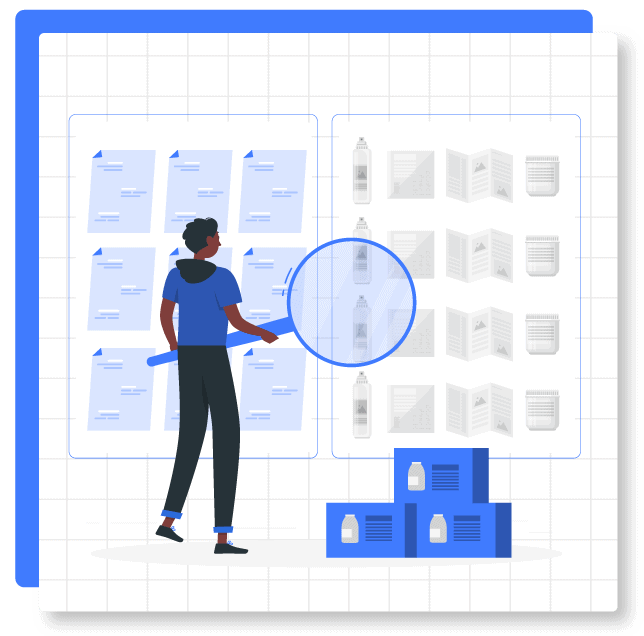

Without proper quality control, the risk of missing a label or packaging error increases exponentially. Despite modern advances in automation technology, many consumer goods companies are still stuck in a rut of manual proofreading. Aside from the social, legal, and financial risk of letting a critical label error slip by, manual proofreading is inefficient and time-consuming, especially in the consumer goods industry.

Any mishap in the packaging quality control process can cause significant delays in getting your products out the door, allowing competitors to get to market faster and putting your brand at a disadvantage. Even a seemingly small error on a product’s barcode can have serious consequences. For example, a product can’t be sold if the barcode doesn’t properly scan at checkout, potentially leaving CPG companies with entire batches of unsellable inventory. Fortunately, automation technology for quality control is becoming more easily accessible and widely implemented across regulated industries.

Protect CPG Labels and Packaging with Automated Quality Control

With automated quality control, brand companies can easily ensure that their labels and packaging are compliant with regulations in all markets. Automated quality control tools can be used at every stage of the proofreading process to ensure 100% accuracy when it comes to critical content.

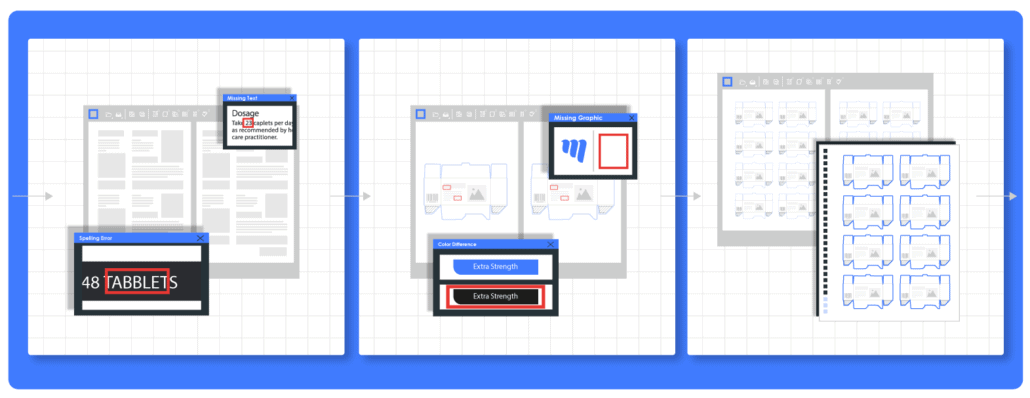

Starting at the copy creation stage, Regulatory, Legal, and R&D departments can automatically inspect content to verify accuracy as product requirements and information are compiled into documents. At this point, automated quality control tools would ensure that all copy documents are error-free as versions are edited before the artwork stage.

At the artwork stage, Creative and Marketing teams can inspect graphics as they create the artwork for labels and packaging components. Common errors that could occur at this stage include logo errors, incorrect product information like allergens or ingredient lists, and barcode or color defects. These types of errors can often be difficult to pick up when visually inspecting each artwork file, so automating this process allows any defects to be picked up with pinpoint accuracy. It’s also important to ensure that the prepress and printers your company is working with have proper quality control tools in place to stop any defects from occurring during the print process.

Finally, labels and packaging can be checked post-production to verify that the final printed label has remained error-free and consistent with the approved artwork. At the final stage, approved files are compared against the incoming supplier proofs to ensure that products make it to market entirely error-free.

A Strong Consumer-Brand Relationship

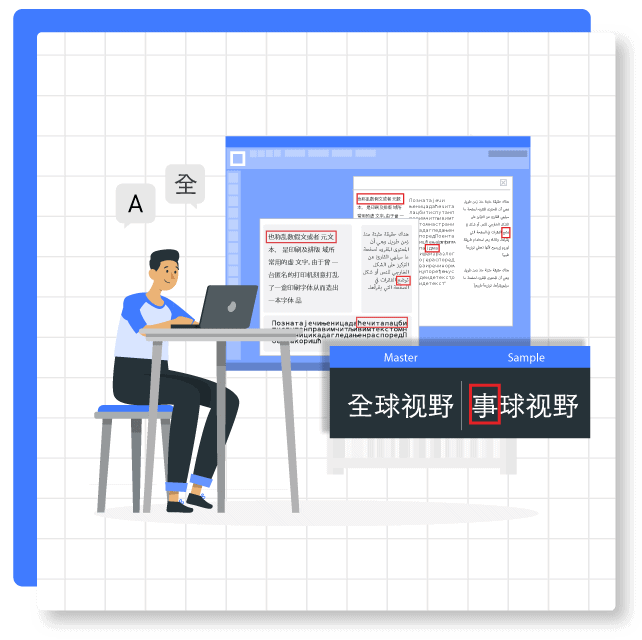

With globalization and products expanding into new markets faster than ever, managing content in foreign languages is critical for companies in the consumer goods industry. Translating content into multiple languages creates significant room for error if only relying on manual proofreading.

Automated quality control systems that are available in today’s market, like GlobalVision, have the ability to digitally proofread and support many foreign languages to ensure that labels are properly adapted for global markets.

While automated quality control may seem like a big initial investment, this type of proofreading technology is quickly becoming a necessity for any consumer-facing company. Consumers have extremely high expectations given the number of options available for brand products, therefore providing full transparency and clarity with a product’s labeling is essential. By helping to create trust between consumers and a brand, automation technology gives brand companies the quality assurance they need to compete on a global scale.

————————————————————————————————————————

Related Articles:

- What are the benefits of implementing a quality inspection system?

- 4 Reasons Why Your Business Needs a Graphics Inspection Tool

- Using Automation Technology to Manage Regulatory Compliance

- Solving The Content Efficiency Problem in the Pharma Industry

- Your Complete Guide to Meeting FDA Labeling Requirements