An Introduction to Automated Quality Control

Date: August, 2023 | Category: Quality | Author: Hana Trokic

Terms like “audit,” “inspection,” and “quality control” are prevalent in any manufacturing business. The first one refers to analyzing manufacturing organizations and processes, whereas the second and third refer to any product-checking activity.

Generally, quality inspectors do this by following a pre-established list based on certain product specifications. In fact, any type of product can be inspected, starting with just the components used for the product to semi-finished ones and (most often) the finished product itself.

According to the ISO 2859 standard – which is derived from MIL-STD 105 E – quality inspection involves activities such as testing, gauging, examining, or measuring one or more product characteristics.

These quality inspections are usually extremely time-consuming and tedious processes that leave little room for error, due to their critical nature of ensuring product quality and safety.

Thankfully, automated quality control is a cutting-edge technological approach that revolutionizes the way industries ensure product excellence, utilizing advanced systems and algorithms to enhance efficiency, accuracy, and consistency throughout the manufacturing revision processes.

Want to learn more about automation, proofreading, and quality control? Read more content from GlobalVision here!

Quality Inspections – Getting Started Early

Quality inspections in any product lifecycle should begin early.

Starting quality inspections early in the product development lifecycle is essential to minimize errors that may arise during any stage of manufacturing, including development, production, and delivery.

This is a critical concept for product developers since identifying and addressing errors as early as possible can help reduce costs significantly.

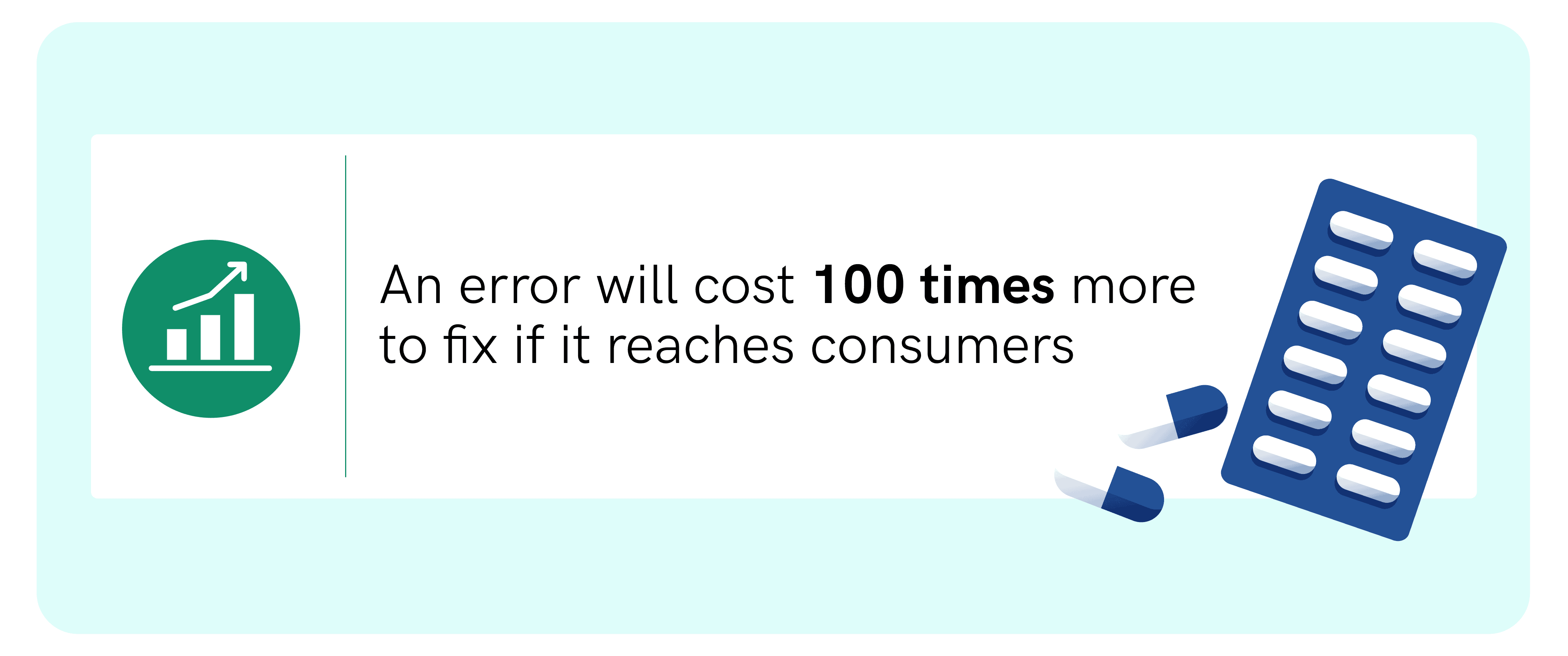

Various studies have shown that there is a 1:10:100 cost/time ratio among the three manufacturing categories. This means that identifying and correcting a mistake during production is likely to cost ten times more, both in terms of time and money, then if it were caught during development.

Following the same ratio, an error will then cost 100 times more to fix if it actually reaches consumers. That’s why applying quality inspection at the end of the production line is a risky move that few major companies dare to take. Big, organized, and customer-oriented companies are now focusing on inspecting earlier to prevent catastrophic consequences and save resources.

Automated Quality Control as a Solution

In order to lower the risk of errors slipping through in all stages of the quality control process, businesses are turning to technology to increase the accuracy of their inspections. Automated quality control is a comprehensive solution that not only allows all differences and errors to be found in critical content, it also speeds up inspections saving businesses time and money.

Businesses can use automated quality control to conduct digital inspections on both hardcopy samples and digital files. This eliminates the need for manual proofreading. By using automated quality control, users can compare sample files to approved content automatically and detect any discrepancies between the two immediately.

The role of automated quality control consists of both speeding up the proofreading process and improving the accuracy of content. To learn more about automated quality control read our detailed blog post here.

How Automated Quality Control Gets Products to Market Faster

Automated quality control technology helps businesses get products to market faster without compromising quality. By automating manual tasks that would otherwise take hours to complete, this technology speeds up the entire quality control process and significantly cuts down proofreading time. In turn, errors can be detected quickly and accurately as inefficiencies like fatigue and human error are eliminated.

Some benefits of implementing automation technology in your business’ quality control process include:

Time benefits of automated quality control

- Eliminates hours spent searching content for errors

- Inspects files in seconds compared to hours spent manually proofreading

- Automatically detect all types of errors at any stage of the process

- Achieve faster turnaround times by accelerating approvals and reducing quality delays

Efficiency benefits of automated quality control

- Easily compare two files to detect any differences between the two

- Identify any touchpoints within your business that are prone to errors

- Utilize time usually spent on proofreading to bring jobs to market faster

To find out more about how automated quality control speeds up product time to market, read our blog post.

Automated Quality Control for Increased Efficiency

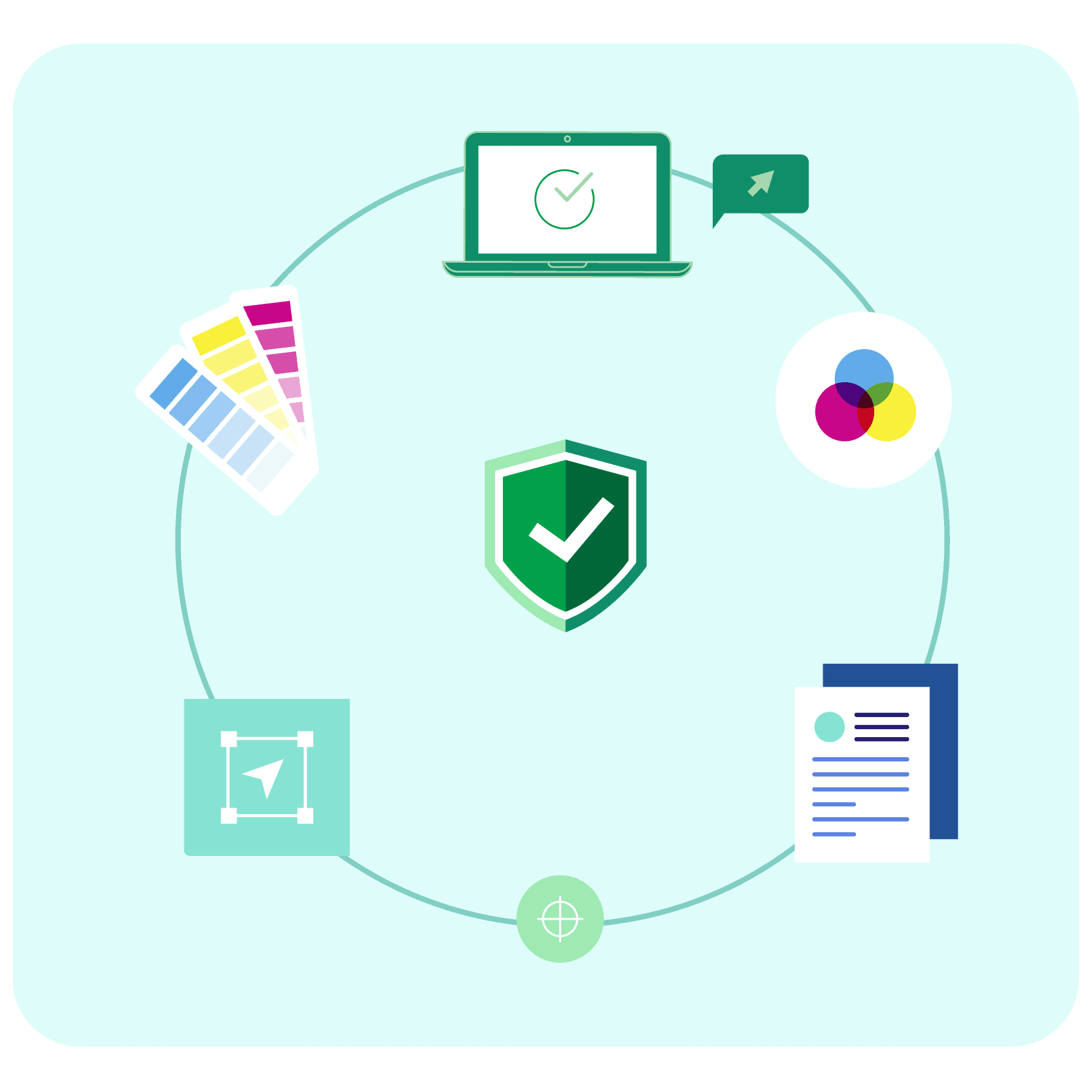

Automated proofreading software simplifies workflow processes, leading to better, more efficient processes. In order to increase productivity in the workplace, practices need to be instilled that allow businesses to get tasks completed more quickly without compromising on the quality of the work.

The implementation of automated quality inspection will enable corporations to rely entirely on digital verification while almost completely reducing and eliminating the need for manual proofreading.

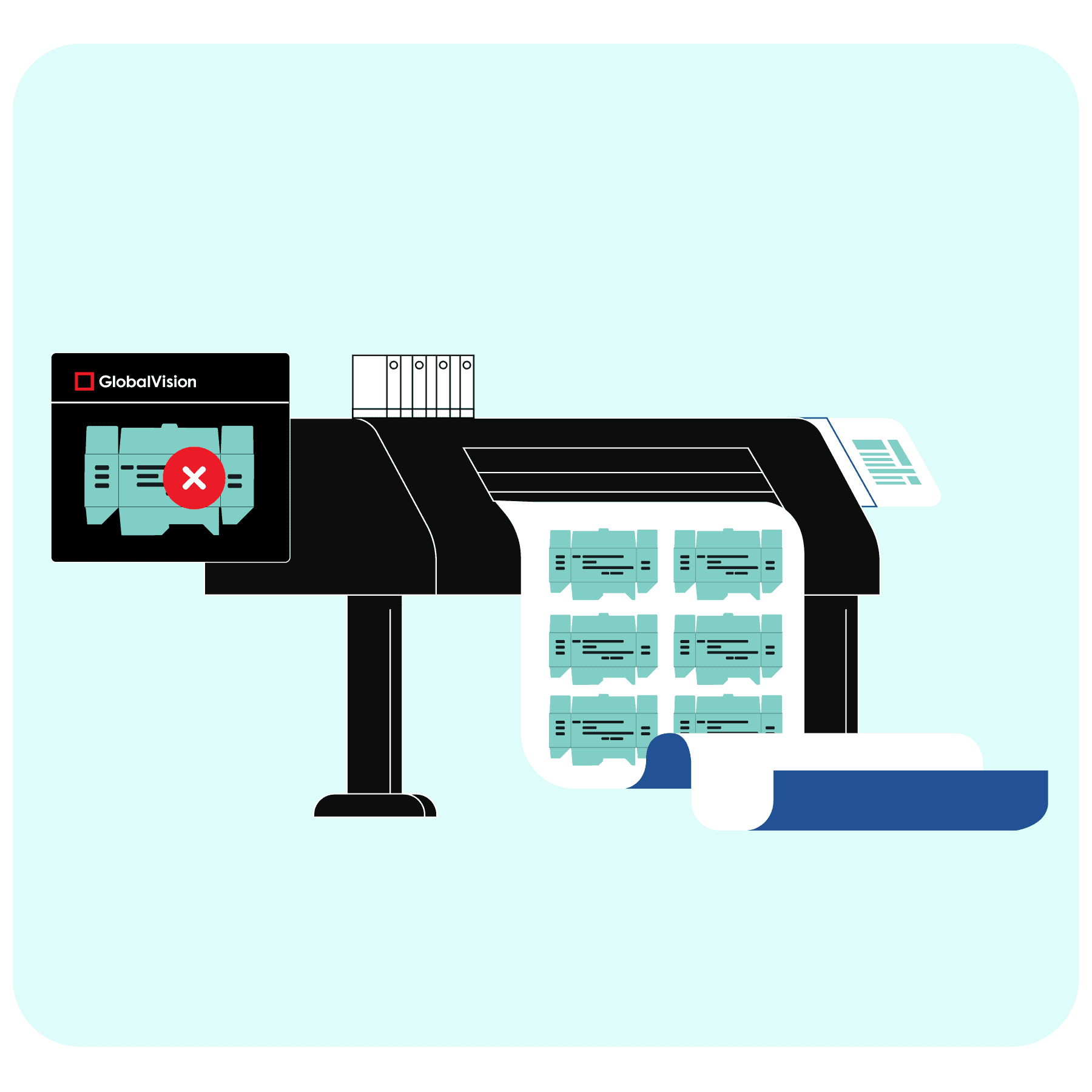

Automated proofreading eliminates the need for overly complicated processes and simplifies to only a couple of steps. Once content is created, the software inspects the entire file looking for discrepancies in the master document and the print.

Errors will be identified within seconds, with the software pinpointing all differences in the document. All that’s left is for quality control teams to make the necessary corrections, and the content is ready to be printed and published.

The software also eliminates the need for large teams to overlook proofreading processes and brings it down to just a few people and the software. Proofreading times are also heavily decreased as the software thoroughly inspects all aspects of the document finding errors that would be extremely difficult to find through manual inspections, such as those of colour, graphic, and barcode deviations.

Find out more about how you can increase efficiency with automated quality control here.

Industry Benefits of Automated Quality Control

Automated quality control presents many benefits for diverse industries operating within regulatory markets. It not only ensures stringent compliance with regulatory standards and guidelines it also efficiently detects deviations and errors, reducing the likelihood of non-compliance and associated penalties.

Some industries that can extremely benefit from automated quality control include:

Automation for Pharmaceuticals

Automation for Pharmaceuticals

Automated quality control benefits pharmaceutical companies by ensuring accuracy, reducing errors, and speeding up processes. It helps meet regulatory standards, brings products to market faster, and provides valuable data for continuous improvement.

Automated inspections for pharmaceuticals have become essential to the day-to-day affairs of companies wishing to attain the efficiency and error-free work that is demanded of them. In addition to the rigorous quality control implemented on the products themselves, it is important to ensure the compliance of packaging and labeling information.

If labels and packaging components are not up to the same quality standards as the products themselves, there could be detrimental consequences to both the brand and the consumer. In this article, we explore the numerous ways that automated packaging inspections can benefit the pharmaceutical industry.

Ensure the accuracy of your critical pharmaceutical content through automation.

The Importance of Quality Inspection in Print and Packaging

Companies needing to print in bulk will find that having a quality inspection process is extremely beneficial. Print inspection systems can provide the assurance and quality control your company needs to minimize mistakes. They will also guarantee the delivery of consistent results that will enhance your brand’s image through error reduction.

In fact, the role of quality inspection systems becomes even more vital when dealing with offset commercial printers. Given that most printing presses operate at incredibly high speeds, irregularities in the final product are more than possible, if not mandatory.

Quality inspection software in print and packaging – as opposed to manual inspection systems – provides the necessary accuracy to achieve consistent and flawless results on a regular basis.

Modern Solution for Prepress

Modern print inspection systems consist of advanced technology that links with your printing press or web rewinder to achieve exceptional results. It works by integrating vision systems (cameras), web viewers, and high-tech software that will catch any errors in time before they are printed in bulk.

Over the years, these quality inspection systems have been developing at a rapid pace. Nowadays, you can find multiple options online at very competitive prices. In fact, given that they require little to no maintenance, one of the key advantages of implementing these non-traditional tools is that you only need to make a one-time investment. Other benefits include ease of use and operation and the ability to have more control over your result.

Benefits of Automation for Creative Agencies

Quality control systems are essential to ensuring that no content errors affect the quality of campaigns and other projects.

Built to ensure the quality of work at all stages of the agency workflow, GlobalVision’s software eliminates inefficient and costly errors that can delay projects and negatively impact client satisfaction. Manual proofreading simply isn’t accurate enough to meet the defined standards that clients expect from their hired agencies, especially when multiple departments are involved.

The various divisions of a creative agency require standardization when it comes to quality control, which is where GlobalVision’s software comes in. From ensuring the accuracy of copies and vendor proofs to graphic and editorial consistency, automated quality control elevates your agency’s credibility and inspires confidence in your clients.

Everything you need to know about automated quality control for creative agencies is right here.

The Role of Quality Control in Consumer Goods

Automated quality control has emerged as a game-changer for the Consumer Packaged Goods (CPG) industry, revolutionizing the way manufacturers ensure product excellence. By leveraging advanced technologies like machine learning and computer vision, automated quality control streamlines and optimizes various aspects of production.

It enhances accuracy and consistency in inspecting content, identifying defects, and monitoring the manufacturing process.

With real-time data analysis, potential issues can be detected swiftly, reducing the risk of faulty products reaching consumers. This not only enhances overall product quality but also minimizes waste and recalls, resulting in cost savings for CPG companies.

Furthermore, automation eliminates the need for extensive manual inspections, freeing up human resources for more strategic tasks, such as research and development, fostering innovation, and driving long-term growth in the industry. Overall, automated quality control empowers the CPG sector to deliver higher-quality products, bolster consumer trust, and maintain a competitive edge in a dynamic market landscape.

Automated Proofreading to Replace Obsolete Difference Checker Tools

According to official Food and Drug Administration numbers, the majority of product recalls are caused by labeling errors. How can companies accurately keep track of the quality of millions of products being packaged daily? It’s definitely a challenge, but that’s why proofreading is crucial in order to release products into the market with complete confidence.

Over the last 20 years, companies have come to realize that human inspection is inherently prone to error. There’s no arguing that, as safety regulations are continuously increasing, automated inspection has become the gold standard for the industry.

Early on, ”diff checker” and ”text compare” tools were the ultimate proofreading solution in the market, allowing for the comparison of characters between two documents and spotting changes in the text before they reach the printer to ensure data integrity.

With the advent of sophisticated machine vision systems and automated proofreading software, technology is progressively becoming more powerful, efficient, and easier to set up and use.

Modern text inspection tools can even generate progress reports, outlining all errors corrected for faster approval times. Meanwhile, plain old document comparison software continues to fall behind when it comes to innovation.

Read more about how automated proofreading is replacing obsolete difference checker tools.

Automate Your Workflows for Success

Quality inspection is an essential part of every production line.

Those who do not understand how valuable they are, are not looking at the big picture. Money-wise, the cost of manufacturing a product extends far beyond the build cost, as it continues across its lifecycle, from support and delivery to warranty claims.

The one-time investment in quality inspection software can reduce future costs relating to customer support, warranty returns, and rejected or returned items. They can even add value to your company, as you’ll count on a competitive defense tool that will eventually pour more money into your pockets.

Ready to step into the world of automated quality control? Request a demo of our innovative proofreading software and see how this technology can revolutionize your everyday business practices.

Transform your quality control processes with GlobalVision’s cloud-based quality inspection tool.