5 Ways to Optimize the Pharmaceutical Labeling Process

Date: August 31, 2021 | Category: Quality | Author: Kayla Caticchio

Product development and manufacturing are at the forefront of any pharmaceutical company’s business activities. Research and development, as well as product innovation help, are key factors in differentiating one company from another in the pharmaceutical landscape.

In such a competitive and regulatory environment, a successful product market integration is essential to the success of your company. Packaging and labeling processes are critical to ensure that products are brought to market as quickly, efficiently, and cost-effectively as possible.

In this article, we’ll explore 5 ways pharmaceutical companies can optimize their packaging and labeling processes.

Pharma Packaging and Labeling

With the majority of resources allocated toward product development and manufacturing procedures, packaging and labeling processes can sometimes be an afterthought.

With the majority of resources allocated toward product development and manufacturing procedures, packaging and labeling processes can sometimes be an afterthought.

Labels and packaging components are just as important as the products inside when it comes to the pharmaceutical and life sciences industry.

With extremely regulated health requirements, mislabeling your product can have serious financial, legal, and safety implications for the brand. In foreign markets, not complying with local labeling guidelines can cost a company hundreds of thousands of dollars in wasted inventory that can’t be sold. Packaging defects also include defective containers, mispackaging, and label mix-ups.

Understanding the importance of a proper labeling process is essential to ensure organizational efficiency and the long-term success of the company.

Best Practices to Optimize Pharma Labeling Processes

Here are 5 ways your company can optimize the pharmaceutical labeling process:

1. Standardizing Labeling Procedures

1. Standardizing Labeling Procedures

Creating a standardized labeling process will allow your company to reduce much of the pressures it faces in terms of efficiency and operational costs. Meeting increasingly demanding regulatory requirements, gaining greater control of your supply chain, and increasing productivity are just a few of the benefits that integrating a standardized labeling process within your company can bring. The standardization process also eases the means of entry into new market opportunities by enabling a method of production that can be easily adapted to suit different packaging and labeling regulations from various regions.

2. Linking Data Directly to the Source

2. Linking Data Directly to the Source

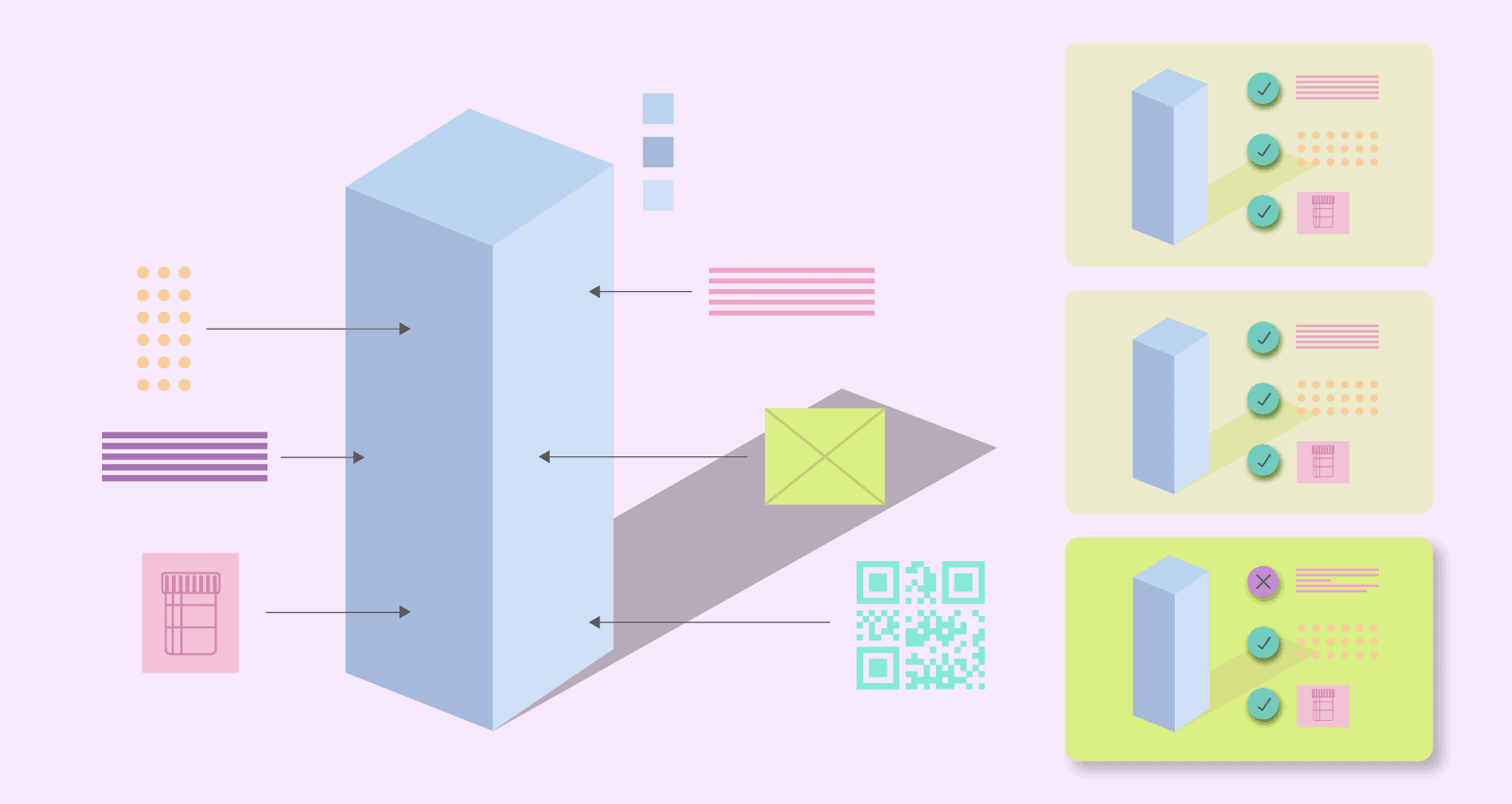

Tools such as a cloud system can help manage and update any regulatory data for products across various platforms and departments. This allows companies to systematically decrease the number of mistakes and inaccuracies that can occur on labels and packaging.

3. Using Automation Tools to Streamline Workflow

3. Using Automation Tools to Streamline Workflow

When it comes to quality control, the use of automated tools has several benefits to a company’s operations. Automation helps streamline workflows while enabling the traceability and accountability of changes that may have been made on labels and packaging files.

4. Centralize Data

Having all of your data gathered into a single, centralized system will increase the efficiency of information and data traveling within your company. Furthermore, it will mitigate the risks of communication mishaps. This is especially relevant when entering new markets where labels and packaging will need to be updated to comply with the targeted market requirements.

5. Prepare for the Unexpected

5. Prepare for the Unexpected

When discussing the importance of standardization, digital tools like automated quality control and cloud-based systems can help businesses prepare for any unexpected setbacks that may occur in their workflow. Having information that pertains to your labeling process readily available at all steps of the pharmaceutical workflow will reduce long project delays and the risk of letting a critical labeling error slip by.

The Pharmaceutical Labeling Process for Your Business

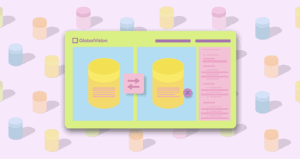

The pharmaceutical landscape is composed of ever-changing local and international regulations. As a result, companies require vigorous quality control standards across all processes. GlobalVision’s automated quality control tools ensure that files remain error-free from creation all the way through to production, allowing businesses to sign-off with confidence that their labels and packaging are accurate.

The pharmaceutical landscape is composed of ever-changing local and international regulations. As a result, companies require vigorous quality control standards across all processes. GlobalVision’s automated quality control tools ensure that files remain error-free from creation all the way through to production, allowing businesses to sign-off with confidence that their labels and packaging are accurate.

To learn more about the Pharmaceutical Labeling Process, click here.

———————————————————————————————————————————————————

Related Resources:

- Solving The Content Efficiency Problem in the Pharma Industry

- Your Complete Guide to Meeting FDA Labeling Requirements

- To learn more about GlobalVision’s automated quality control tools, click here.

- Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

- Keep up with the latest updates in automated quality control. Sign up for our newsletter.