What the Digital Twins Revolution Means for Packaging

Date: June, 2017 | Category: Proofreading | Author: Ryan Szporer

Digital twins are in the midst of taking over, with Gartner predicting the existence of billions of them within three to five years.

It’s probably best at this point to shake that image that’s likely in your head of a group of villainous, goateed doppelgangers hell-bent on world domination. A huge technological trend that cannot be ignored instead, digital twins are becoming more and more crucial to the manufacturing process.

Digital Twins Explained

For the uninitiated, a digital twin, as the term relates to a product life cycle, is exactly what it sounds like. You have something physical that you can touch and a replica that has digitally captured all the same properties to track changes and project where those changes will lead.

It’s not a 3D model of a given product, but a software model of that product’s inner workings… everything that contributes to its physical existence. In this case, the whole is greater than the sum of its part and provides an in-depth look into the potential for the future.

From a purely financial standpoint, the reasoning is sound. If a given company has the means to create digital versions of assets, of various sizes up to and including entire factories to represent real-world environments for simulation and analytical purposes, why not? The sensor data gleaned can only help to increase efficiency and the bottom line.

That goes for improving customer relations as well, with even more of a financial benefit to be had if a firm is able to take advantage in such a fashion. Whereas initial uses focused primarily on products, digital twins’ horizons have sufficiently broadened over time to the point that systems, series of processes, and even entire operations can be digitally duplicated as well.

Benefits include the ability to detect deficiencies before individual products hit the market, the resulting optimization of their design and functionality, and continuous refinement thanks to captured data. Updates and changes are theoretically made in real-time, with a single source of truth or data shared between the twins. This aspect in particular, as it relates to copy management, can be extended to product packaging.

Two Copies, One Version

It may not be out of the ordinary for companies to post PDFs of their products’ packaging on their websites. However, it is common to find discrepancies between what customers find in stores and what’s online, which can pose a serious problem, especially in industries like pharma. The smallest errors can have serious ramifications, with outdated information posing huge risks from customer health and subsequently liability standpoints.

In such a hypothetical scenario, you’ve got two versions of the same packaging. Only one of them’s (presumably) correct. Both of them should be.

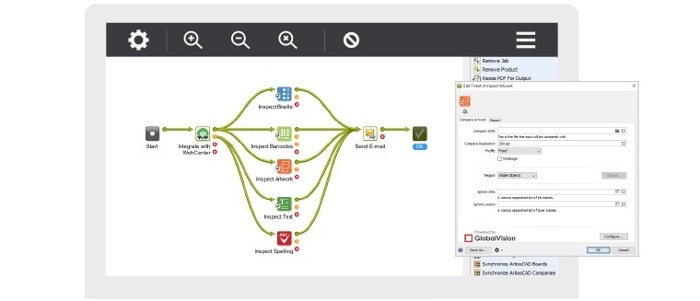

A digital twin in the form of a webpage would in theory be updated with the physical copy so that no one version will lag behind the other. Automating quality control software like GlobalVision to run in the background helps ensure there are no mistakes and that the two are identical moving forward.

It’s just one application of what is a rapidly increasing trend, which in and of itself is arguably just the next step. That’s the next step in terms of prototyping and not our evolution, to be clear. Although, we have undeniably come to a point where the digital world means just as much as the real one.

Companies should have long since come to the realization that it’s not just about the physical product anymore. A lot of factors enter into the equation when a company tries to map out what will be successful after all. Whether digital twins are the next step or stop on the road to making a profit, there’s simply no avoiding them.

GlobalVision is the leading developer of proofreading technologies for retail and consumer packaged goods.

Learn how GlobalVision can help ensure data integrity using Automated Proofreading.

Request a free trial for GlobalVision Digital Inspection Solution

Learn More about the Everlasting Benefits of Taking the Proofing Process into the Digital Age