Make Quality Your Competitive Advantage

Increase customer acquisition with a powerful inspection system that helps your business achieve continuous growth.

Make Quality Your Competitive Advantage

Increase customer acquisition with a powerful inspection system that helps your business achieve continuous growth.

Join the thousands of companies worldwide who trust GlobalVision with their quality control

The Proactive Approach to

Quality That Gives Your

Business a Competitive Edge

Position yourself as a leader in quality automation and innovation with secure and verified technology that sets your business apart from the competition.

Open doors for new business opportunities across all industries by showing potential customers that you’re willing to invest in a system that provides an extra layer of security.

The Proactive Approach to Quality That Gives Your Business a Competitive Edge

Position yourself as a leader in quality automation and innovation with secure and verified technology that sets your business apart from the competition.

Open doors for new business opportunities across all industries by showing potential customers that you’re willing to invest in a system that provides an extra layer of security.

Protect Customers From the Risk of Errors

Produce high-quality labels and packaging that reduce the risk of a costly recall, saving customers from potential damage to their reputation.

Protect your business and brand equity by catching critical errors before they get printed and make it out the door.

Protect Customers From the Risk of Errors

Produce high-quality labels and packaging that reduce the risk of a costly recall, saving customers from potential damage to their reputation.

Protect your business and brand equity by catching critical errors before they get printed and make it out the door.

Show Customers You Go the Extra Mile

Give your clients the added assurance that extensive quality checks are being performed in your production facility.

Keep costs low by reducing the risk of having to throw out batches of printed materials due to printer errors.

Show Customers You Go the Extra Mile

Give your clients the added assurance that extensive quality checks are being performed in your production facility.

Keep costs low by reducing the risk of having to throw out batches of printed materials due to printer errors.

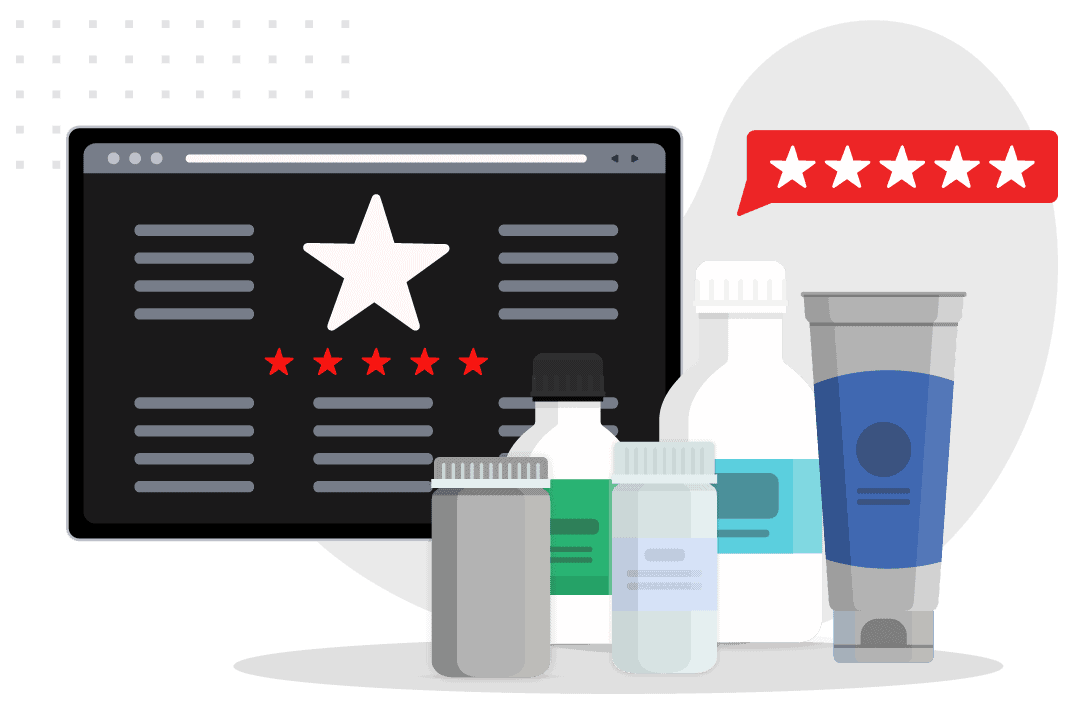

See What Our Customers Are Saying About GlobalVision

Achieve Your Business Goals With GlobalVision

Get a personalized demo today.