How Automation Streamlines the Quality Control Process

Date: July, 2021 | Category: Proofreading | Author: Kayla Caticchio

What are the Benefits of Automation?

Automation comes in many forms and covers a wide array of modern technologies that can operate without the help of consistent human intervention or supervision. The first benefit that emerges from this is the idea of reducing workloads. Having an automation system or software implemented at various stages of your workflow will allow you to spend more time on other projects and leave you with additional resources.

Automation technology also reduces operating costs by employing fewer people for the same or greater amount of output while increasing consistency and efficiency by eliminating operating errors.

What are the Benefits of Quality Control?

Quality control ensures that uniformity and high standards of business practices can be maintained over the course of your company’s day-to-day production processes.

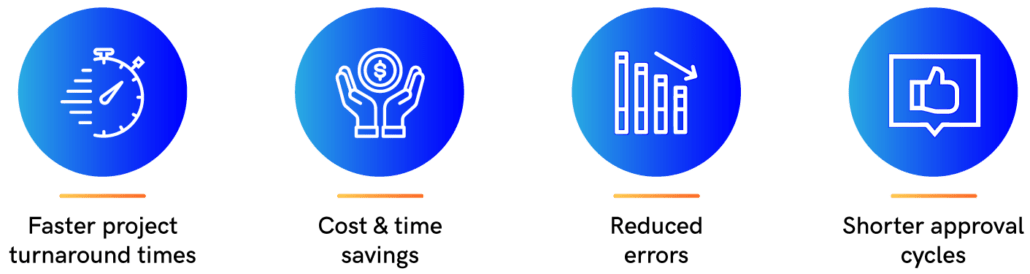

Automated quality control at various revision points helps you identify deviations as they occur before they accumulate and become unmanageable. Utilizing the benefits of quality control will allow your company to maximize resources and human output by benefitting from:

Click here to learn more about the benefits of implementing a quality inspection system. GlobalVision’s inspection platform offers the benefits of quality control through reliable end-to-end solutions for various departments. The reputation of every company is dependent on its products, therefore ensuring that no product is released with critical defects is the main reason for establishing quality control within business operations.

What is Automated Quality Control?

Automated quality control enables businesses to run digital quality inspections on hardcopy samples and digital files, eliminating the need for manual proofreading. With automated quality control, users can automatically compare sample files against approved content to immediately detect any differences between the two.

The role of automated quality control consists of both speeding up the proofreading process and improving the accuracy of your work with consistent results. Learn more about automated quality control here.

What are the Advantages of Automated Quality Control?

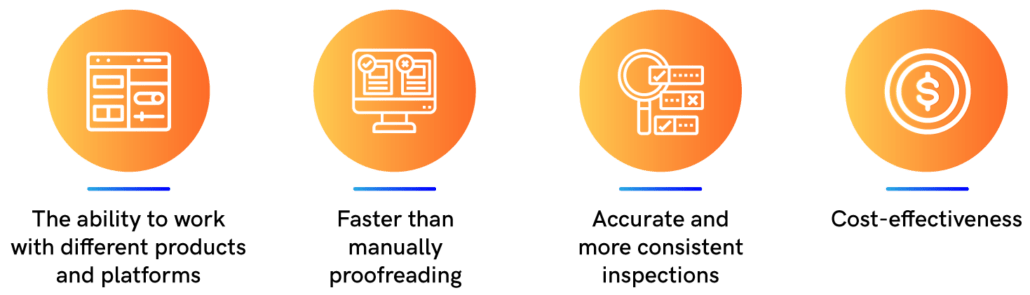

The need for better and higher productivity results in this growing digital age has helped highlight where automated inspections may come into play. The advantages of automation in quality control include:

Simple tasks, such as proofreading and editing, can be handled through automated systems more effectively. They find errors in your work before they become problems while leaving more time and opportunity for creative processes and/or more complex tasks.

Related Articles:

- What are the benefits of implementing a quality inspection system?

- What is a quality management system?

- The Everlasting Benefits of Taking Your Proofing Process into the Digital Age

- Ensure your content is always error-free in record time with GlobalVision. Try it now for free.

- Keep up with the latest updates in automated quality control. Sign up for our newsletter.